Foam roll order

Foam roll

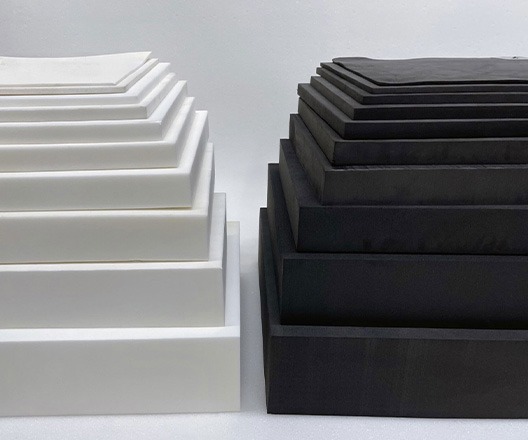

Foam sheets are boiled in a welding machine to create a foam roll. This roll is then cut horizontally into various thicknesses using a foam roll-cutting machine. Different types of foam, such as EVA foam, TPE foam, EPDM foam, and polyethylene foam, have unique properties, and their production rolls are used across various industries. These products have quality management certificates, including ISO 45001 safety and health management and ISO 14001 environmental management, as well as ISO 9001: 2015 certification.

Types of foam rolls

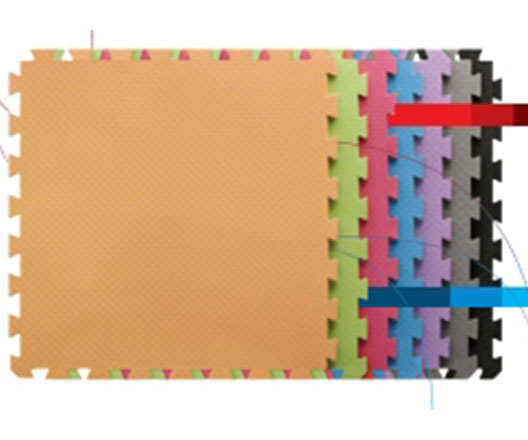

- Foam rolls come in different varieties and are used in various industries. A simple foam roll is a smooth surface without any design or lamination of fabric, leather, etc.

- On the other hand, patterned foam rolls have a textured surface that can create more than 20 types of thermal and molding foam rolls. These textured rolls are used to prevent slipping and are commonly used in the production of slippers and sandals, such as hotel sandals and disposable sandals.

- Silent parquet floor rolls are used to prevent damage to the parquet. These high-quality rolls are ideal for use in homes and offices, as they prevent the parquet from getting damaged when walked on. Parquet foam is also used to prevent energy loss. This product can be installed under the parquet to prevent cold air from entering and heat from escaping outside.

Foamiran Company produces different types of foam rolls in various dimensions and thicknesses. The foam production plant produces all kinds of rolls daily, according to the specific needs of customers in different thicknesses.

Features of foam roll

Foam roll has a unique closed-cell structure that prevents the growth of bacteria and fungi.

- Lightweight

- Flexible and resilient

- Making it resistant to chemical agents

- Capable of absorbing shocks and vibrations

- Custom-made to meet specific requirements

- Waterproof, sound insulation, heat and cold

Applications of foam sheet

Foam is a versatile material with a wide range of applications across various industries. Below are some examples of how foam is used in different industries:

- Production of bags and shoes

- Automotive industry (washers and seals)

- Cleaning industry (floor washing foams, glass washing, etc.)

- Production of sports equipment such as yoga mats, yoga bricks, and all kinds of sports flooring

- Packaging Industry

- Shipbuilding industry

- Construction industry (Silent foam Parquet)

- Medical industry (knee braces, neck braces, and all kinds of medical and orthopedic equipment)

Foam roll products

Technical Data

Click the link provided to download technical information on foam roll.

Services

Click on the provided link to download services foam roll.

Frequently Asked Questions

What type of foam sheets do you manufacture?

Fomiran produces a variety of foam layers and sheets, including EVA foam, CR neoprene, TPE, EPDM, EPDM/NBR, polyethylene, compressed foam, and more.

What is the best thickness for a silent parquet foam roll?

Usually, the best thickness for silent parquet foam is 2 mils, as foam that is too soft can cause noise and potentially damage the parquet.