Shipbuilding industry

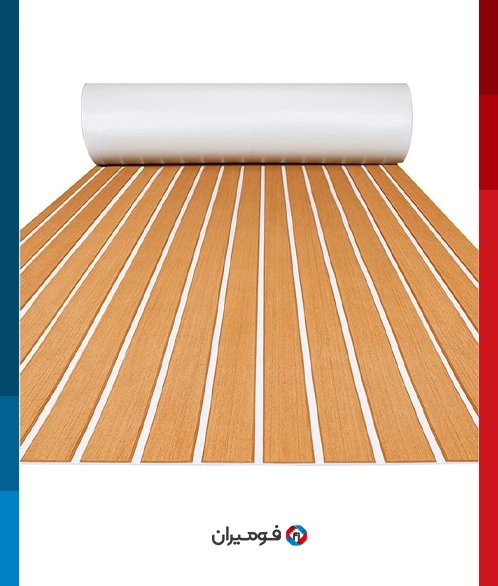

Foam is considered one of the most widely used materials in the shipbuilding industry because it is both lightweight and durable, and also offers high performance against moisture and impact. From insulating various parts of a ship to the safety of floorings and foam bumpers, this material plays a vital role in increasing the durability, safety, and comfort of marine spaces. On this page, you can learn about various types of foam suitable for marine and industrial applications and easily place your bulk order.