EVA and PE foam with second-stage curing (TVRG)

Consulting and ordering

Order from the foamiran factory

What is TVRG Foam?

The formation of TVRG foam is an innovative polymer technology that uses polyethylene (PE) or ethylene-vinyl acetate (EVA) as its base materials. Its main distinction from conventional foams lies in the curing method. While typical foams are cured in a short time and at high temperatures, TVRG foam is produced through a two-stage process at a moderate temperature over a longer period. This allows the internal cells of the foam to form in a completely orderly and closed manner, creating a uniform and durable structure. The result of this process is a foam that surpasses traditional types in durability, dimensional stability, elastic performance, and resistance to harsh environmental conditions.

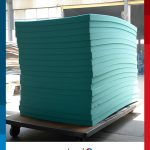

Depending on its intended application, TVRG foam is produced in two main categories. The first type is PE-based, which is a lightweight, soft, and low-density foam suitable for packaging and light industries. The second type is EVA-based, offering higher density and strength, making it ideal for heavy industries such as automotive manufacturing, shipbuilding, industrial components, and transportation equipment. Flexibility in material formulation and production technique allows Foamiran to customize TVRG foam according to the specific needs of each industry, in various thicknesses, densities, and tailored properties.

TVRG Foam Products

Technical Data

To download the technical information of the low-density TVRG foam, click the button opposite.

To download the technical information of the high-density TVRG foam, click the button opposite.

Features of TVRG Foam

Product introduction video for TVRG Foam

TVRG Foam Production Technology at Foamiran

Foamiran’s TVRG foam represents the fusion of industrial experience and modern engineering technology. This product is manufactured through a two-stage curing process at balanced temperatures — a crucial factor in its superior quality. In this technology, the initial mixture of polyethylene (PE) or ethylene-vinyl acetate (EVA) undergoes a molecular cross-linking process that creates inter-chain bonds. Following this, the foam is cured under controlled conditions. The first stage involves initial shaping at a lower temperature, while the second stage completes curing at a moderate heat over a longer period.

Unlike conventional foams, which are cured rapidly under high heat, this method gradually increases the temperature and then maintains it at a constant level, allowing the internal cells to develop completely and form a seamless, dense structure. The result is a foam whose density, strength, dimensional stability, and durability far surpass standard market products.

Differences Between TVRG Foam and Regular Foam

In conventional foams, rapid curing and high heat cause internal cells to form irregularly. Over time, and under sustained pressure, this irregularity leads to quality degradation, surface collapse, and dimensional distortion. In contrast, TVRG foam’s two-stage curing allows the cells to expand gradually, preventing the breaking of molecular bonds within the structure. This precise time control creates a uniform, stable, and long-lasting foam that maintains its shape under continuous pressure or prolonged heat.

In essence, the difference between TVRG and traditional foams lies in three key aspects: longer curing time, precise temperature control, and the formation of closed cells throughout the depth of the material. Together, these factors result in both mechanical and economic superiority.

Material Composition and Two Base Types

Material composition plays an essential role in the performance of TVRG foam. Foamiran manufactures this foam using two base types.

The first is PE-based TVRG foam, produced with low-density polyethylene. It is lightweight, soft, and flexible, designed for applications that require low weight, high shock absorption, and flexibility—such as precision packaging for sensitive components, shock absorbers, lightweight sound insulation, and protective product layers.

The second is EVA-based TVRG foam, made from ethylene-vinyl acetate. This composition increases the foam’s density, hardness, and elastic strength, making it suitable for heavy-duty industries like automotive manufacturing, shipbuilding, locomotives, and industrial components. It exhibits high endurance against pressure, vibration, and heat.

By using these two bases, Foamiran can fully tailor TVRG foam according to the needs of each industry. For example, clients can request specific hardness, desired color, defined thickness, or even particular rebound levels—all incorporated during the formulation stage.

Structural and Physical Characteristics

Internally, TVRG foam features uniform, closed cells. This structure prevents the infiltration of water or vapor, giving the foam excellent moisture resistance. The cellular uniformity also ensures consistent mechanical strength throughout the material.

Physically, the foam is lightweight, easy to cut, suitable for lamination, and highly abrasion-resistant. Its low weight is a major advantage in production lines, simplifying transport and installation. The precise, uniform texture ensures smooth and clean edges upon cutting or molding, eliminating the need for reprocessing.

Thermally, TVRG foam demonstrates remarkable stability. It retains its form under high temperatures and does not become brittle in cold conditions. This broad temperature tolerance makes it ideal for use across diverse environments—from severe cold to operational heat.

Advantages of the Two-Stage Curing Technology

One of Foamiran’s greatest achievements in TVRG foam production is its two-stage curing technology, which offers several major benefits:

- Enhanced cell uniformity and improved compression resistance.

- Maintains structural integrity even in thicker foam sheets.

- Continuous temperature control reduces energy consumption, making the process more economical.

- Extended curing time ensures stronger molecular bonds, resulting in superior strength and durability.

Consequently, TVRG foam performs consistently under harsh environmental conditions, prolonged pressure, and extreme temperature fluctuations. This resilience is particularly essential in heavy industries such as rail transport and shipbuilding, where vibrations and temperature variations are constant.

Production in Various Sizes and Thicknesses

A distinct advantage of TVRG foam over standard foams is its ability to be produced in larger sheet sizes and greater thicknesses without compromising internal quality. This unique two-stage process enables Foamiran to manufacture industrial-scale sheets and one-piece blocks with enhanced structural integrity.

Even at greater thicknesses, TVRG foam maintains its flexibility and rebound performance—an indicator of its high production precision and advanced cell expansion control.

Pressure and Impact Resistance

Despite being lightweight, TVRG foam offers exceptional mechanical strength under compression. When subjected to pressure, its internal cells compress and then instantly return to their original state once the force is removed. This rebound capacity prevents permanent deformation.

Additionally, due to its closed-cell structure, impact energy is dispersed and absorbed evenly, increasing resistance to crushing. For this reason, TVRG foam is widely used as a shock absorber in protective packaging and safety flooring.

Thermal, Acoustic, and Moisture Insulation

Owing to its closed-cell nature, TVRG foam is one of the most effective multi-purpose insulators available. It minimizes heat transfer, maintaining thermal stability, and reduces noise by blocking sound transmission through its dense structure.

Its moisture resistance is equally superior — no water is absorbed within the cells as each one is completely sealed. These qualities make it suitable for the construction, HVAC, and infrastructure industries, where insulation against temperature, noise, and humidity is vital.

Industrial Applications

TVRG foam has a wide range of industrial uses. In the automotive sector, it serves as an insulator for sound, heat, and vibration in vehicle interiors and flooring. In shipbuilding, it is used as an anti-vibration and environmental-resistant foam in hulls and infrastructure. In rail and locomotive industries, it reduces vibration in floors, ceilings, and cabin panels. It also functions as protective packaging for delicate products against shock, vibration, and humidity.

In construction, due to its tri-fold insulation (thermal, acoustic, and moisture), it is used in walls, ceilings, and flooring systems. The sports industry also adopts it for flooring, training mats, and safety gear.

Chemical Resistance and Long Service Life

Another advantage of TVRG foam is its high chemical resistance. It does not react or disintegrate when exposed to many weak acids, bases, or solvents, making it safe for industrial environments where chemical contact is likely.

Additionally, this foam retains its durability under exposure to sunlight, UV radiation, seasonal temperature changes, and high humidity. Unlike traditional foams that stiffen or crack over time, TVRG foam maintains flexibility and structural integrity even after years of use.

Economic Advantages and Customization Capability

Beyond its physical and mechanical benefits, TVRG foam is economically efficient. The optimized production process reduces energy and raw material consumption while maintaining top-tier quality. Moreover, since Foamiran manages full domestic production, all material specifications can be finely adjusted.

Customers can customize the color, density, thickness, dimensions, and even surface texture of the foam based on their exact requirements. This level of customization has made TVRG foam a preferred choice in diverse industries—from bag and footwear manufacturing to medical equipment and defense applications.

Frequently Asked Questions

What is the difference between TVRG foam and regular foam?

In the TVRG method, the curing process takes place over a longer time and at balanced temperatures, resulting in more uniform internal cell formation and significantly greater foam durability.

What materials is TVRG foam made of?

This foam can be made from polyethylene (PE) or EVA, with the first type suitable for light applications and the second type designed for heavy industries.

Is TVRG foam waterproof?

Yes, its closed-cell structure prevents the penetration of water and vapor, making the foam completely moisture-resistant.

In which industries is TVRG foam used?

The main applications include automotive manufacturing, shipbuilding, locomotive production, industrial packaging, sports flooring, and construction.

Is the thickness of TVRG foam adjustable?

Yes, it can be produced in various thicknesses, densities, and colors according to customer specifications.

How resistant is TVRG foam to pressure?

Thanks to its two-stage curing process and stable cellular structure, TVRG foam does not deform under continuous pressure or heavy impact.

How can TVRG foam be purchased?

You can contact Foamiran’s sales department at +98‑21‑54917000 or submit your order through the online order form.