Industrial Applications of T-Foam Sheet

Due to its diverse properties and unique features, T foam sheet is used in a wide range of industries. Factories and manufacturers can benefit from this product to improve the quality and efficiency of their own products. Below are some of its most important industrial applications:

1. Military and Defense Industries

The military industry requires materials that are durable, lightweight, and resistant to harsh environmental conditions. T foam sheet is widely used in this sector for the following reasons:

Packaging for Sensitive Equipment: To protect electronic components, precision instruments, and optical equipment from shock and vibration during transport and storage. The high shock-absorption property of T foam prevents damage to this valuable equipment.

Insulation: Used in creating thermal and acoustic insulation for military vehicles, shelters, and communication equipment. Its resistance to water and moisture is also crucial for protecting equipment in humid environments.

Protective and Shock-Absorbing Parts: Used in the production of personal protective gear, knee and elbow pads for military personnel, as well as in helmets and impact-resistant vests. The lightweight and flexible nature of T foam provides necessary comfort and effectiveness.

Flooring and Interior Linings: Used in making anti-slip and shock-absorbing flooring for vehicles and military facilities that require high durability and comfort.

2. Medical and Healthcare Industries

The medical industry requires materials that are hygienic, washable, hypoallergenic, and resistant to liquids. T foam sheet meets these requirements well:

Orthopedic and Support Pads: Used in making braces, orthotics, and support pads for patients and individuals undergoing rehabilitation. The softness and flexibility of T foam ensure patient comfort.

Medical Shoes and Insoles: Used in the production of orthopedic insoles and specialty footwear for individuals with foot problems, due to its shock-absorbing properties and arch support.

Medical Equipment: Used in the internal components of some medical devices, such as pressure-relief mattresses and specialized pillows. Its waterproof nature is essential for easy cleaning and maintaining hygiene.

Sterile Packaging: For packaging surgical instruments and sensitive medical equipment that require a sterile and protected environment.

3. Automotive Industry

In the automotive industry, T foam sheet is used to improve the performance, safety, and comfort of vehicles:

Acoustic and Thermal Insulation: Used in interior door panels, flooring, and ceilings to reduce noise and improve the thermal insulation of the cabin. This enhances passenger comfort and improves the driving experience.

Vibration and Shock Dampeners: Used in various parts of the car body to absorb vibrations and impacts, increasing the lifespan of mechanical parts.

Sealing and Gasketing: Used for seals in doors, windows, and trunks to prevent the infiltration of water, dust, and noise.

Automatic Car Wash Brushes: As mentioned earlier, brushes made from EVA foam are used in automatic car washes for the safe and effective cleaning of vehicles.

4. Sports and Recreation Industries

Due to its light weight, softness, water resistance, and shock absorption, T foam is widely used in the production of sports and recreational products:

Kickboards and Swim Barbells: Used to produce foam kickboards and swim barbells for swimming instruction and aquatic exercises. These products are lightweight, buoyant, and resistant to chlorinated water.

Exercise and Yoga Mats: Used in making exercise and yoga mats that require a soft, non-slip, and shock-absorbing surface.

Protective Pads: Used in creating protective pads for various sports like football, hockey, and skiing to protect joints and the body from impact.

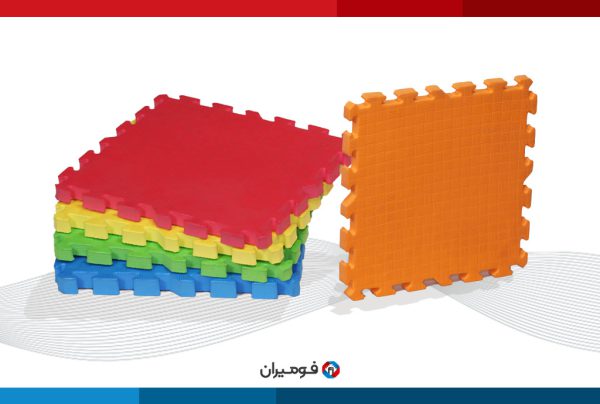

Playground and Gym Flooring: To create a safe and shock-absorbing surface in children’s playgrounds and sports clubs.

5. Packaging Industry

The shock-absorbing capability and flexibility of T foam make it an ideal material for packaging:

Protective Packaging: For packaging sensitive and fragile products such as electronic components, laboratory equipment, and glassware. T foam can be custom-designed to fit the product precisely.

Dividers and Liners: Used in boxes and containers as dividers to prevent contact and damage between products.

6. Construction Industry

In the construction industry, T foam is used to improve insulation and increase safety:

Thermal and Acoustic Insulation: Used in walls, ceilings, and floors to reduce heat and sound transmission.

Sealers and Weatherstripping: To fill gaps and joints and prevent the infiltration of water and air.

Anti-Slip Flooring: In wet and high-traffic areas such as bathrooms and industrial kitchens.