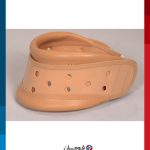

Today, EVA foam is in high demand in the market due to its exceptional quality and applications. Its history of innovation in packaging medical devices and pharmaceuticals is long and successful. Medical foam, known for its high flexibility, softness, and rebound properties, is utilized to produce orthopedic equipment such as medical necklaces and shoe insoles.

Foam Products Characteristics in Medical Industries

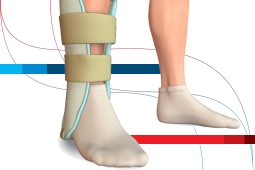

In the medical industry, foam is utilized to create necklaces, knee pads, leg braces, and wristbands. These foams have continuous skin contact, are washable, anti-fungal, and don’t promote bacteria growth or infections. Additionally, the significance of medical foam’s lightweight quality is important in medical equipment, as it must not add excessive pressure or burden to the patient. Medical foams are extremely light and take the shape they are given.

Orthopedic foam, which is soft, comfortable, and lightweight, is an ideal choice for making ergonomic, medical, and durable chairs.

Noise reduction in medical facilities

Hospitals can be noisy places for patients due to activities such as walking or moving equipment. This problem is somewhat resolved by using foam rolls for parquet flooring, also known as Silent Foam.