Types of Granular Flooring | Rubber Flooring

These floorings are made in various types, each with its own specific application. You can choose them according to your needs or preferences.

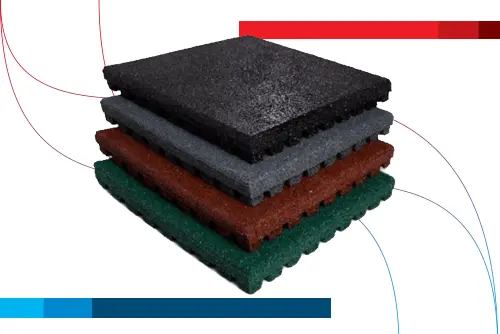

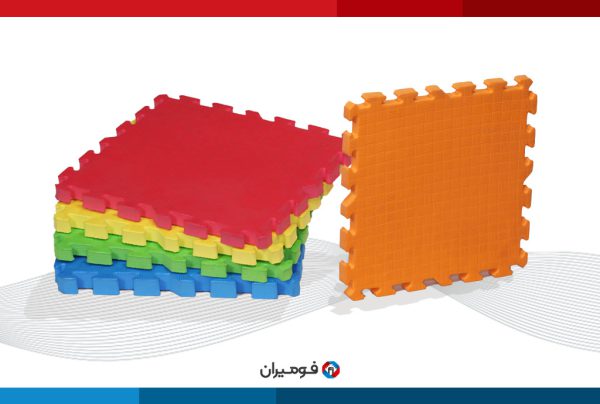

One-Meter Flooring Tiles

One-meter flooring tiles have dimensions of one meter by one meter, forming a square. When you want to install them, you must place them side-by-side, much like mosaic tiles. It is important to note that one-meter tiles are available in thicknesses of 20, 25, 30, 40, 50, and 70 mm. Another name for this granular flooring is “flat” tile.

Half-Meter Flooring Tiles

This type of flooring is similar to the one-meter version in terms of its shape and dimensions, with the difference being that its dimension is half a meter.

Egg Crate” Style Flooring

The “egg crate” style flooring is made in one-square-meter dimensions, with a square shape. The base of the tile is raised, resembling an egg carton, and it is used for outdoor spaces and parks. The thickness of this type of flooring is between 40 and 45 mm.

Rolled Granular Flooring

This type of flooring, similar to the flat tiles, is made in one-square-meter dimensions. Using modern equipment and materials, it has become possible to produce flooring with finer granules. These types of floors are called “rolled” flooring. In terms of appearance, this product is very similar to carpet. The pressing process for this flooring is different from others. Rolled flooring is made in thicknesses of 5 to 25 mm.

Poured-in-Place Park Flooring

When recycled granules are mixed with an adhesive and applied directly onto the desired location, a type of flooring is created that resembles asphalt and is called “poured-in-place.” The thickness of this flooring is between 15 and 20 mm.