Foam Components: Functional and Flexible Elements for Modern Industries

Foam components are essential elements in many products and systems, highly valued for their flexibility, shock absorption, insulation, and sealing properties. These parts are made from various types of foam and are designed for specific technical roles in industries such as automotive, construction, electronics, medical, and packaging.

Despite their simple appearance, foam components play a crucial role in enhancing product performance, durability, and comfort. From pads and gaskets to thermal insulators and shock absorbers, these components work behind the scenes to improve efficiency and protect devices and systems.

This article explores foam components, their features, benefits, applications, and key design considerations.

2. What Are Foam Components?

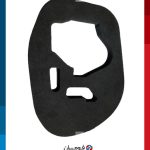

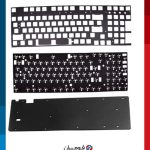

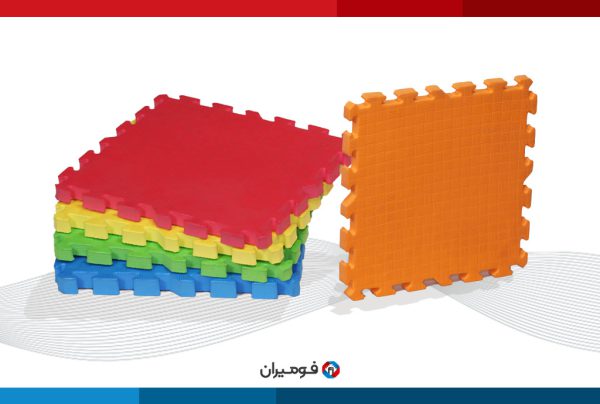

Foam components are die-cut or molded parts made from soft or rigid foams, serving mechanical or protective functions. Unlike general-purpose foam, these parts are precisely designed for specific industrial or commercial applications.

They may include seals, pads, spacers, bumpers, liners, or embedded elements. Manufacturing processes include die-cutting, CNC machining, thermoforming, or molding. The type of foam is chosen based on intended performance: impact absorption, thermal insulation, sound dampening, sealing, or vibration control.

3. Foam Materials Used

-

Polyethylene (PE): High durability and waterproof

-

Polyurethane (PU): Soft, flexible, and resilient

-

EVA: Lightweight with excellent shock absorption

-

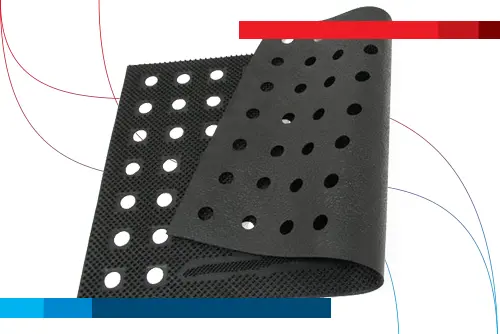

Neoprene or Rubber Foams: Resistant to heat, oil, and compression

-

PVC and Silicone: Suitable for extreme temperatures and tough conditions

Foams are produced in open-cell and closed-cell structures. Closed-cell foam is ideal for sealing and insulation, while open-cell foam provides softness and breathability.

4. Advantages of Foam Components

5. Applications of Foam Components

-

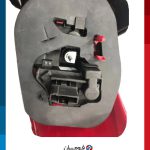

Automotive: Dashboard insulation, sealing strips, sound-dampening pads

-

Electronics: Cable separators, gaskets, thermal insulation

-

Construction: Joint fillers, sound and heat insulation

-

Medical: Sanitary pads, splints, cushions

-

Packaging: Protective inserts, box liners

-

Sports Equipment: Impact foam, clothing insulation

6. Considerations and Limitations

-

Compatibility with environmental factors (temperature, UV, chemicals)

-

Compression set resistance and recovery

-

Proper adhesion to different surfaces

-

Recyclability and environmental impact

-

Higher cost at low production volumes

7. Conclusion

Foam components are not merely fillers—they are precision parts that provide vital functions across industries. From shock absorption to sealing, they improve the safety, durability, and quality of products.

With high customizability, low weight, and affordable production, foam components play a key role in modern manufacturing. As the demand for multifunctional materials grows, foam components will continue to evolve and expand their presence in industrial applications.

FAQs

Q1: Which industries use foam components the most?

A: Automotive, electronics, construction, medical, packaging, and consumer goods.

Q2: Are foam components fire-resistant?

A: Yes, many types of foam offer fire-retardant properties.

Q3: Are foam components recyclable?

A: Some foams, like PE, are recyclable, though it depends on the type and application.