What is LDPE Foam? ✧

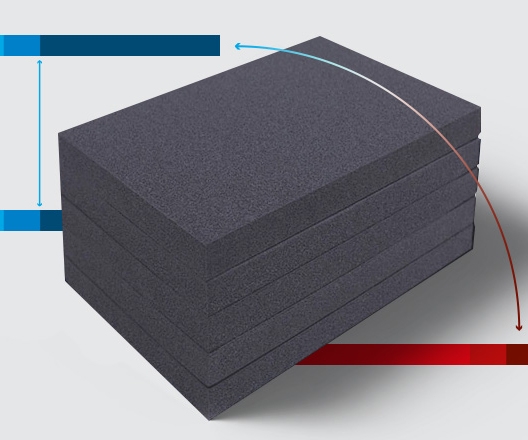

LDPE foam, also known as LDPE foam, is a type of plastic foam made from low-density polyethylene. Thanks to its unique properties—such as being lightweight, excellent shock absorption, high flexibility, and moisture resistance—it has found extensive applications across various industries. This material features a closed-cell structure that prevents water penetration and inhibits the growth of microorganisms, allowing it to maintain exceptional durability even in humid environments.

In other words, LDPE foam strikes a perfect balance between strength and softness. It feels as soft as a pillow yet acts as a robust shield against impacts. Because of these combined qualities, it’s widely used in many fields, ranging from packaging and insulation to medical and sports equipment.

Key Advantages of LDPE Foam

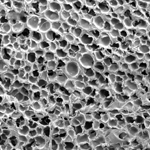

- Closed-cell structure

LDPE foam consists of closed cells that block moisture, vapor, and suspended particles from penetrating. This not only prevents water and liquid absorption but also inhibits the growth of fungi, mold, and bacteria. As a result, this type of foam is an ideal choice for use in moist, sanitary environments such as cold storage facilities, industrial kitchens, medical centers, and even specialized children’s equipment. Additionally, this characteristic contributes to the foam’s extended lifespan and easier maintenance.

- Superior shock absorption and cushioning properties

One of the most outstanding features of LDPE foam is its high capacity for shock absorption. Its cushion-like structure absorbs energy from impacts and vibrations, protecting both products and individuals from damage. This makes LDPE foam a preferred material for packaging delicate items like medical equipment, electronic components, and glassware. It is also widely used in manufacturing sports flooring and protective gear for physical training.

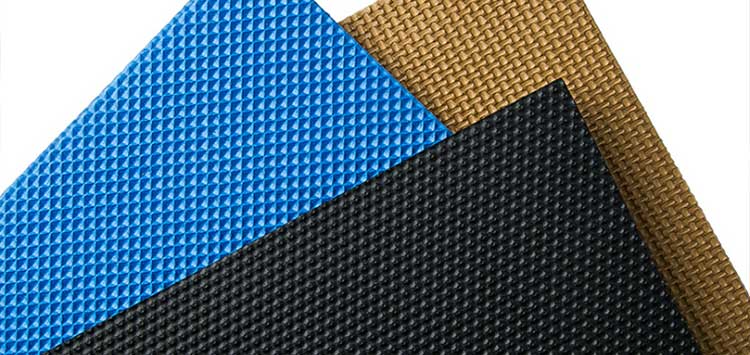

- High flexibility and rapid shape recovery

LDPE foam is highly flexible and resists deformation under pressure. Once the pressure is released, it quickly returns to its original shape. This property makes it particularly suitable for applications requiring continuous pressure endurance, such as sports pads, industrial shock absorbers, and reusable products.

- Lightweight and highly portable

Thanks to its low density, LDPE foam is exceptionally lightweight, which facilitates transportation and installation. In contexts where weight is critical—like portable medical devices, lightweight sports pads, or mobile protective gear—LDPE foam plays a crucial role. Its lightness also helps reduce transportation costs.

- Thermal and acoustic insulation

Naturally resistant to sound, heat, and cold transmission, LDPE foam serves as an effective insulator in industrial, construction, and acoustic applications. It’s commonly used in flooring, wall panels, soundproofing systems, and ventilation units, helping prevent energy loss while creating a quieter, more isolated environment.

- Resistance to water, chemicals, and oils

LDPE foam isn’t just water-resistant; its unique chemical composition also makes it stable against many solvents, oils, and chemicals. This makes it well-suited for industrial environments, production lines, laboratories, and even exposure to corrosive substances.

- Easy cleaning and maintenance

When surface contamination occurs, LDPE foam can be easily cleaned using water and mild detergents. It dries quickly after washing and retains its original quality. This makes it an excellent option for use in places requiring high hygiene standards, such as kindergartens, sports clubs, and public facilities.

- Stable performance across a wide temperature range

LDPE foam performs reliably in temperatures ranging from -40°C to +105°C (-40°F to +221°F). This allows it to withstand cold storage conditions, outdoor environments, and areas near heat sources without losing its shape, insulating properties, or physical integrity.

Major Applications of LDPE Foam Across Industries

- Packaging Industry

With its high shock absorption, lightweight nature, and easy cutting and molding capabilities, LDPE foam is an ideal material for packaging sensitive products like electronic equipment, industrial parts, glass, and ceramics.

- Acoustic and Sound Insulation

Egg-crate shaped versions of this foam are used to reduce sound reflection and diffuse sound waves in indoor spaces such as studios, cinemas, and conference rooms. Thanks to its wavy structure and low density, acoustic LDPE foam lowers sound echoes and improves audio quality.

- Construction Industry

LDPE foam is used as an insulating material for walls, floors, and ceilings. Its placement beneath parquet or ceramic flooring helps control sound and heat transmission.

- Automotive Industry

This foam is employed in producing gaskets, cushions, cabin sound insulation, hood liners, and vibration damping in vehicles. Its flexibility and resistance to varying temperatures make it highly suitable for automotive applications.

- Medical Equipment

LDPE foam is used for sterile packaging of medical devices or as bases for machines and protective pads. Its lightweight and washable nature are key benefits in this field.

- Electronics Industry

It protects electronic components, sensitive circuit boards, and accessories from vibrations. Foam inserts in hardware packaging boxes are often made from LDPE foam.

- Sports Goods Manufacturing

Used in lightweight protective gear such as pads, training shoes, and workout cushions. Its excellent shock-absorbing properties help prevent injuries during physical activities.

- Vehicles, Pipelines, and Storage Tanks

Used as a thermal insulating layer on pipelines and tanks. Also applied in public transportation vehicles like train and metro cars.

Why Choosing LDPE Foam for Your Project is a Smart Decision?

| Feature |

Benefit |

| Lightweight |

Easy transportation and installation; cost savings on shipping |

| Closed-cell structure |

Resistant to moisture, fungi, mold, and bacterial growth |

| Strong shock absorption |

Protects against physical damage and extends product lifespan |

| Flexible |

Easily shaped and adaptable to various forms and conditions |

| Chemical and thermal resistant |

Suitable for harsh industrial environments |

| Sound and heat insulation |

Creates a safe, quiet environment and reduces energy consumption |

| Easy to clean |

Perfect for clean and hygienic environments like hospitals and kitchens |

Download the LDPE Foam (LDPE) Datasheet

For detailed technical specifications, densities, hardness levels, and application guides for each type of LDPE foam, you can download the full datasheet via the link below:

Download the LDPE Foam Datasheet

Final Summary

LDPE foam is a versatile product featuring a closed-cell structure, high quality, and unique properties that make it suitable for a vast range of applications—from acoustic and thermal insulation to impact-protective packaging, from construction to automotive and medical equipment. If you’re looking for a lightweight, durable, flexible, and washable material for your project, LDPE foam is a professional and cost-effective choice.

For practical consultation or to request samples, please contact Foamix experts or specialized vendors to select the product best suited to your needs.

What is LDPE Foam? ✧

LDPE foam, also known as LDPE foam, is a type of plastic foam made from low-density polyethylene. Thanks to its unique properties—such as being lightweight, excellent shock absorption, high flexibility, and moisture resistance—it has found extensive applications across various industries. This material features a closed-cell structure that prevents water penetration and inhibits the growth of microorganisms, allowing it to maintain exceptional durability even in humid environments.

In other words, LDPE foam strikes a perfect balance between strength and softness. It feels as soft as a pillow yet acts as a robust shield against impacts. Because of these combined qualities, it’s widely used in many fields, ranging from packaging and insulation to medical and sports equipment.

Key Advantages of LDPE Foam

- Closed-cell structure

LDPE foam consists of closed cells that block moisture, vapor, and suspended particles from penetrating. This not only prevents water and liquid absorption but also inhibits the growth of fungi, mold, and bacteria. As a result, this type of foam is an ideal choice for use in moist, sanitary environments such as cold storage facilities, industrial kitchens, medical centers, and even specialized children’s equipment. Additionally, this characteristic contributes to the foam’s extended lifespan and easier maintenance.

- Superior shock absorption and cushioning properties

One of the most outstanding features of LDPE foam is its high capacity for shock absorption. Its cushion-like structure absorbs energy from impacts and vibrations, protecting both products and individuals from damage. This makes LDPE foam a preferred material for packaging delicate items like medical equipment, electronic components, and glassware. It is also widely used in manufacturing sports flooring and protective gear for physical training.

- High flexibility and rapid shape recovery

LDPE foam is highly flexible and resists deformation under pressure. Once the pressure is released, it quickly returns to its original shape. This property makes it particularly suitable for applications requiring continuous pressure endurance, such as sports pads, industrial shock absorbers, and reusable products.

- Lightweight and highly portable

Thanks to its low density, LDPE foam is exceptionally lightweight, which facilitates transportation and installation. In contexts where weight is critical—like portable medical devices, lightweight sports pads, or mobile protective gear—LDPE foam plays a crucial role. Its lightness also helps reduce transportation costs.

- Thermal and acoustic insulation

Naturally resistant to sound, heat, and cold transmission, LDPE foam serves as an effective insulator in industrial, construction, and acoustic applications. It’s commonly used in flooring, wall panels, soundproofing systems, and ventilation units, helping prevent energy loss while creating a quieter, more isolated environment.

- Resistance to water, chemicals, and oils

LDPE foam isn’t just water-resistant; its unique chemical composition also makes it stable against many solvents, oils, and chemicals. This makes it well-suited for industrial environments, production lines, laboratories, and even exposure to corrosive substances.

- Easy cleaning and maintenance

When surface contamination occurs, LDPE foam can be easily cleaned using water and mild detergents. It dries quickly after washing and retains its original quality. This makes it an excellent option for use in places requiring high hygiene standards, such as kindergartens, sports clubs, and public facilities.

- Stable performance across a wide temperature range

LDPE foam performs reliably in temperatures ranging from -40°C to +105°C (-40°F to +221°F). This allows it to withstand cold storage conditions, outdoor environments, and areas near heat sources without losing its shape, insulating properties, or physical integrity.

Major Applications of LDPE Foam Across Industries

- Packaging Industry

With its high shock absorption, lightweight nature, and easy cutting and molding capabilities, LDPE foam is an ideal material for packaging sensitive products like electronic equipment, industrial parts, glass, and ceramics.

- Acoustic and Sound Insulation

Egg-crate shaped versions of this foam are used to reduce sound reflection and diffuse sound waves in indoor spaces such as studios, cinemas, and conference rooms. Thanks to its wavy structure and low density, acoustic LDPE foam lowers sound echoes and improves audio quality.

- Construction Industry

LDPE foam is used as an insulating material for walls, floors, and ceilings. Its placement beneath parquet or ceramic flooring helps control sound and heat transmission.

- Automotive Industry

This foam is employed in producing gaskets, cushions, cabin sound insulation, hood liners, and vibration damping in vehicles. Its flexibility and resistance to varying temperatures make it highly suitable for automotive applications.

- Medical Equipment

LDPE foam is used for sterile packaging of medical devices or as bases for machines and protective pads. Its lightweight and washable nature are key benefits in this field.

- Electronics Industry

It protects electronic components, sensitive circuit boards, and accessories from vibrations. Foam inserts in hardware packaging boxes are often made from LDPE foam.

- Sports Goods Manufacturing

Used in lightweight protective gear such as pads, training shoes, and workout cushions. Its excellent shock-absorbing properties help prevent injuries during physical activities.

- Vehicles, Pipelines, and Storage Tanks

Used as a thermal insulating layer on pipelines and tanks. Also applied in public transportation vehicles like train and metro cars.

Why Choosing LDPE Foam for Your Project is a Smart Decision?

| Feature |

Benefit |

| Lightweight |

Easy transportation and installation; cost savings on shipping |

| Closed-cell structure |

Resistant to moisture, fungi, mold, and bacterial growth |

| Strong shock absorption |

Protects against physical damage and extends product lifespan |

| Flexible |

Easily shaped and adaptable to various forms and conditions |

| Chemical and thermal resistant |

Suitable for harsh industrial environments |

| Sound and heat insulation |

Creates a safe, quiet environment and reduces energy consumption |

| Easy to clean |

Perfect for clean and hygienic environments like hospitals and kitchens |

Download the LDPE Foam Datasheet

For detailed technical specifications, densities, hardness levels, and application guides for each type of LDPE foam, you can download the full datasheet via the link below:

Download the LDPE Foam Datasheet

Final Summary

LDPE foam is a versatile product featuring a closed-cell structure, high quality, and unique properties that make it suitable for a vast range of applications—from acoustic and thermal insulation to impact-protective packaging, from construction to automotive and medical equipment. If you’re looking for a lightweight, durable, flexible, and washable material for your project, LDPE foam is a professional and cost-effective choice.

For practical consultation or to request samples, please contact Foamix experts or specialized vendors to select the product best suited to your needs.