Packaging industry

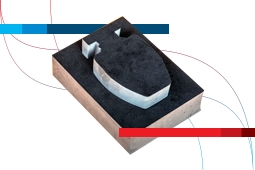

By offering a variety of high-quality foam products, Foamiran perfectly meets the needs of the packaging industry. Our products include foam sheets and pages ideal for protecting goods from impact and damage. These products are designed according to the specific needs of the packaging industry and can be used to package various items, including electronics, glassware, and even food products. With custom foam solutions, Foamiran ensures that your goods reach customers safely and securely.