In many industrial, public, and even semi-domestic spaces, choosing a material that is safe, highly durable, and performs well in various environmental conditions is of great importance. Industrial foams, due to their low weight, flexibility, and ability to be produced in various dimensions and thicknesses, have become one of the most widely used materials in different industries. Among these, honeycomb tread foam has found a special place in the automotive industry, construction, and many humid and high-traffic environments due to its specific structure and significant technical features.

Honeycomb tread foam is not only used for specialized industrial applications but also plays an important role in increasing safety and reducing risks in public spaces such as parking lots, car washes, saunas, and jacuzzis. In this article, we examine fully and understandably what honeycomb tread foam is, what features it has, and why it has attracted attention in various industries, especially automotive and construction.

What is Honeycomb Tread Foam and What are its Features?

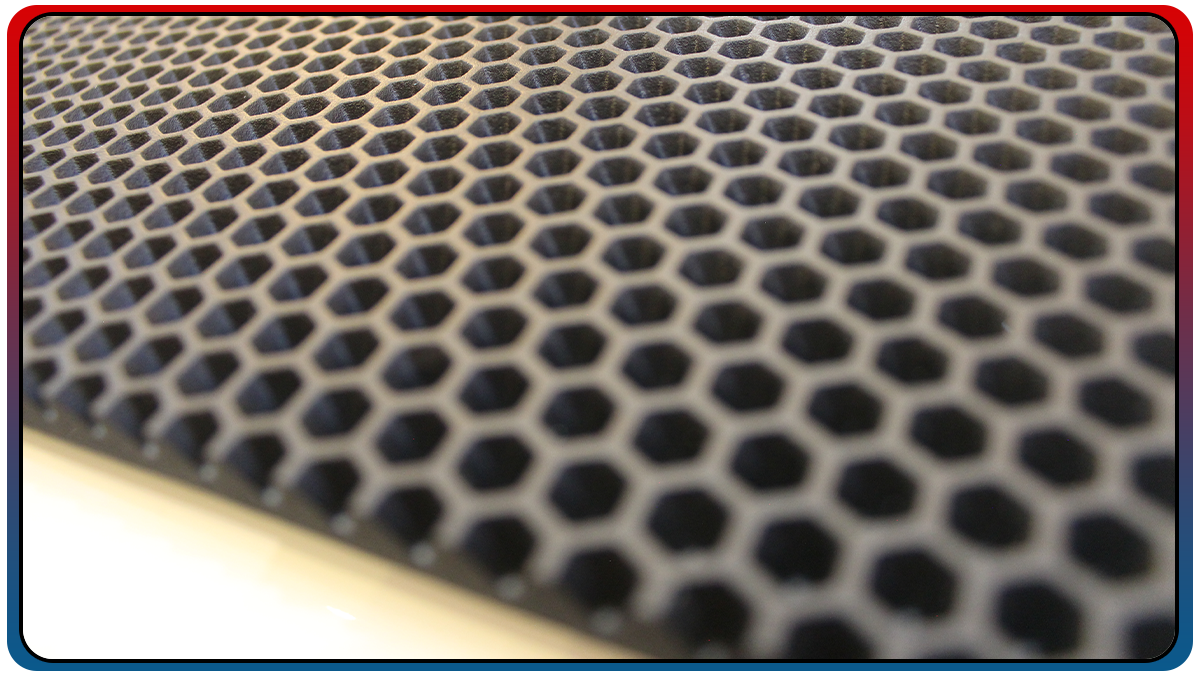

Honeycomb tread foam is a type of industrial foam whose surface features a raised pentagonal and honeycomb-shaped pattern. This specific design is not merely for appearance but has a direct impact on the foam’s performance. The treaded structure increases surface friction and prevents slipping; for this reason, this foam is widely used in humid and slippery environments.

Honeycomb tread foam is a type of industrial foam whose surface features a raised pentagonal and honeycomb-shaped pattern. This specific design is not merely for appearance but has a direct impact on the foam’s performance. The treaded structure increases surface friction and prevents slipping; for this reason, this foam is widely used in humid and slippery environments.

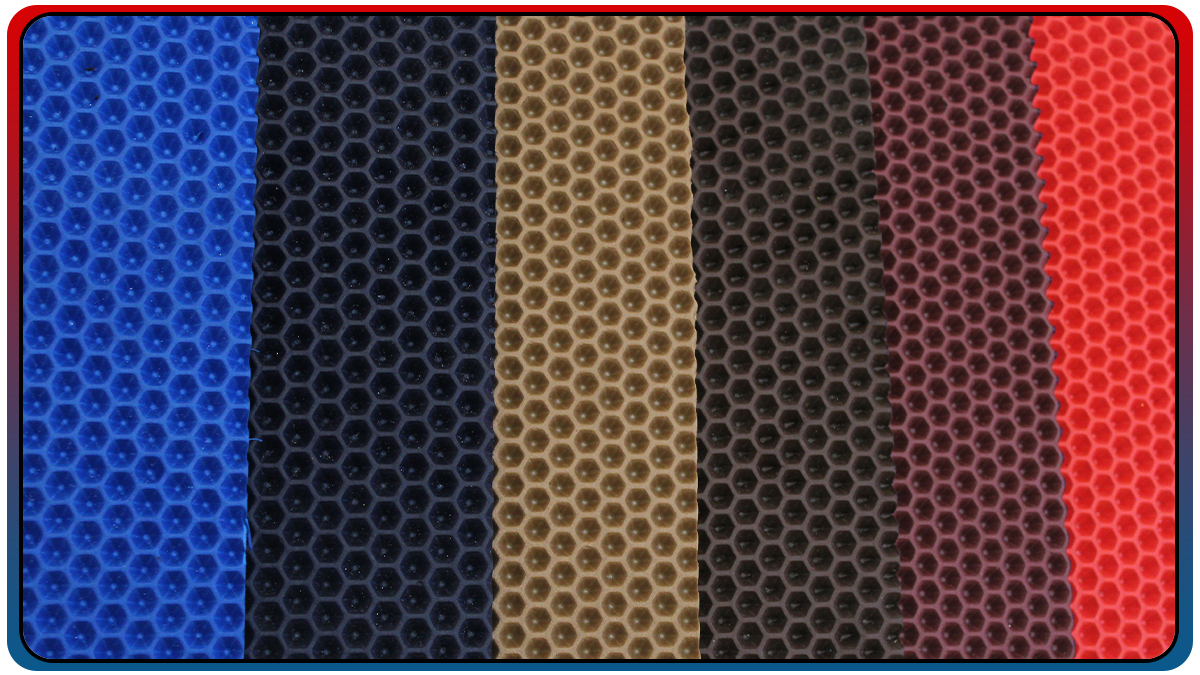

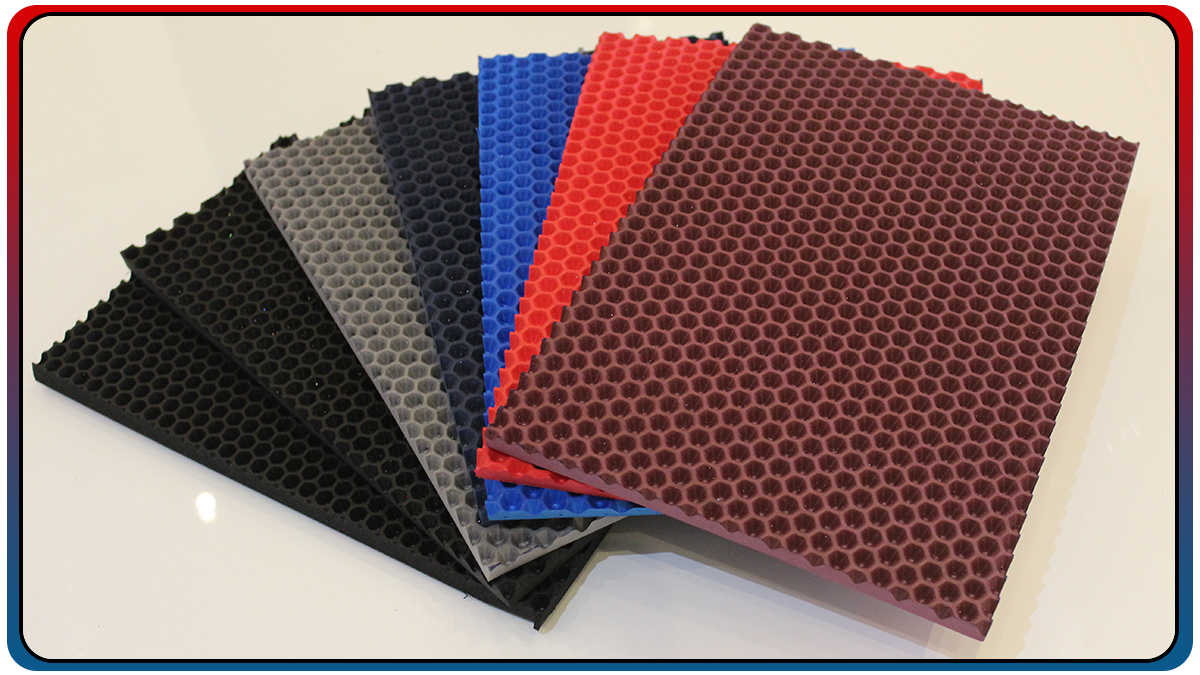

Among the most important features of honeycomb tread foam, one can mention its anti-slip property, resistance to moisture, high flexibility against pressure and impact, suitable resistance to heat and UV rays, and long lifespan. Additionally, this foam can be produced in various and custom colors, making it a suitable choice for different spaces visually as well.

Honeycomb Structure of Tread Foam and its Impact on Performance

One of the most important differences between honeycomb tread foam and plain foams is its honeycomb and pentagonal structure. This design allows for better air circulation on the foam surface and prevents moisture accumulation. This very feature plays an important role in increasing safety and reducing slipperiness.

Furthermore, the honeycomb structure causes uniform pressure distribution across the foam surface. When weight or impact is applied to a specific point, the pressure is spread evenly, preventing severe deformation or damage to the foam. This feature is highly important in spaces with heavy traffic or where heavy equipment is placed on the surface.

❓ Question Box: Why is Honeycomb Tread Foam Important in the Automotive Industry ?

In the automotive industry, noise reduction, vibration absorption, and increasing safety are considered top priorities. Honeycomb tread foam, due to its high flexibility and engineered structure, can play an effective role in improving the overall quality of the vehicle.

This foam is used in parts of the vehicle that are exposed to vibration, impact, or constant contact. Its anti-slip and resistant structure ensures that parts remain fixed in place and prevents the creation of extra noise. Also, the lightweight nature of honeycomb tread foam helps improve the vehicle’s technical performance without increasing its weight.

Applications of Honeycomb Tread Foam in Various Vehicle Parts

In vehicles, honeycomb tread foam is used in various sections. Among its common applications, one can mention its use in the car floor, trunk, doors, and parts of the interior space. This foam acts as a shock absorber layer and sound insulator, increasing passenger comfort.

Also, in some vehicles, honeycomb tread foam is used to reduce component vibration and prevent direct contact between metal surfaces. This issue not only reduces noise but also increases the lifespan of the components.

The Role of Honeycomb Tread Foam in the Construction Industry

In the construction industry, there are many spaces that require a material that is resistant, anti-slip, and suitable for specific environmental conditions. Honeycomb tread foam is considered a suitable option for such spaces due to its resistance to moisture, abrasion, and pressure.

This foam is used in construction projects as flooring, a protective layer, or insulation and can significantly increase environmental safety. The use of honeycomb tread foam in buildings is particularly important in humid and high-traffic areas.

Wide Applications of Honeycomb Tread Foam in Different Environments

The application of honeycomb tread foam is not limited only to the automotive and construction industries. This foam offers excellent performance in environments with slippery surfaces or where there is a need for shock absorption and insulation.

Among the important applications of honeycomb tread foam, one can mention flooring for parking lots and car washes. In these spaces, the presence of moisture and heavy traffic increases the risk of slipping, and honeycomb tread foam can play an effective role in increasing safety.

Deck covering for boats and vessels is another important application of this foam. Resistance to moisture, flexibility, and anti-slip properties have made honeycomb tread foam a suitable choice for marine environments.

Also, in industrial environments and cold storages where the floor is exposed to pressure, abrasion, and temperature changes, the use of honeycomb tread foam is common. Sauna and jacuzzi flooring, due to high humidity and the need for greater safety, is considered another application of this foam.

Comparison of Honeycomb Tread Foam Application in Automotive and Construction Industries

In the table below, the difference in the application of honeycomb tread foam in the automotive and construction industries is summarized:

Advantages of Honeycomb Tread Foam Compared to Ordinary Foams

Compared to smooth foams, honeycomb tread foam performs much better in preventing slips, absorbing shock, and air circulation. High resistance to abrasion and UV rays ensures this foam performs well in open environments too. Also, the possibility of production in various colors makes its use in public and visible spaces easier.

❝

Foamiran CEO’s Statement regarding Honeycomb Tread Foam

“Honeycomb tread foam, due to its honeycomb design and specific technical features, has become one of the widely used materials in various industries. Our focus at Foamiran has always been on producing foams that possess the necessary safety, durability, and efficiency under real industrial conditions.”

What Points Should We Consider When Choosing Honeycomb Tread Foam?

To choose the suitable honeycomb tread foam, factors such as thickness, density, the environment of use, and moisture level must be considered. The correct choice ensures better performance of the foam and increases its lifespan.

To choose the suitable honeycomb tread foam, factors such as thickness, density, the environment of use, and moisture level must be considered. The correct choice ensures better performance of the foam and increases its lifespan.

Conclusion of Honeycomb Tread Foam Applications

Honeycomb tread foam, due to its honeycomb structure, anti-slip property, moisture resistance, and high flexibility, is considered a practical material for various industries. From automotive and construction to parking lots, car washes, boats, and industrial environments, this foam has been able to provide a suitable response to diverse needs.

A Reliable Choice with Foamiran

If you are looking to choose a suitable foam for high-traffic, humid, or industrial environments for your project, receiving specialized consultation can make decision-making easier. The Foamiran group, with experience in producing various industrial foams, is ready to offer solutions tailored to the needs of different projects. For more information and consultation, you can be in touch with Foamiran experts.