Car wash brush foam is a specialized type of foam designed for use in automated or manual car washing equipment. It plays a crucial role in ensuring vehicles are cleaned thoroughly without causing scratches, swirl marks, or other surface damage. These foams are engineered for softness, flexibility, and chemical resistance, allowing them to maintain performance over time even under wet and abrasive conditions. Used in rotating brushes or handheld tools, car wash brush foam comes into direct contact with the vehicle’s exterior, so its quality directly affects both cleaning effectiveness and customer satisfaction. With advancements in foam chemistry and processing, manufacturers can now produce foams that hold water and soap longer, last through repeated cycles, and perform well in both hot and cold climates. Whether for touchless car washes or fullcontact systems, this type of foam has become a key component of modern vehicle cleaning technology.

2. Properties of Car Wash Brush Foam

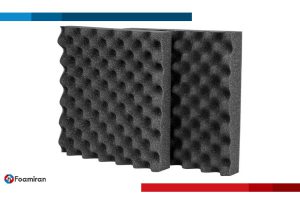

Car wash brush foam must meet several performance criteria to be effective in realworld environments. It needs to be soft enough to avoid damaging automotive finishes, yet strong enough to endure friction, rotation, and repeated exposure to cleaning chemicals. Typically made from closedcell polyethylene or polyurethane, these foams are hydrophobic, quickdrying, and resistant to mildew and mold. The cell structure influences how well the foam retains water and disperses soap during washing.

Other important factors include density, thickness, and abrasion resistance. The foam must also be lightweight to avoid straining motors in automated systems. Some advanced foams feature surface texturing or perforations to improve cleaning efficiency while maintaining surface safety. Antistatic or colorfast additives may be used for specific equipment requirements.

- Softness

- Chemical Resistance

- Water Retention

- Abrasion Strength

- Lightweight

- FastDrying

3. Applications of Car Wash Foam

This foam is primarily used in automated car wash systems, where rotating brushes need to contact vehicles with consistent pressure and movement. Foam strips or pads are shaped to fit brush assemblies and ensure even coverage across different vehicle surfaces like hoods, windows, sides, and bumpers. In manual car washing, the foam may be part of handheld brushes or sponges designed to provide gentle scrubbing action.

Beyond traditional car washes, this type of foam is also used in bus and truck washing systems, where vehicles have larger surface areas and require longer foam contact. Specialty applications include foam integration into wash tunnels for boats, trains, or agricultural vehicles.

The foam can also be found in selfservice car wash kits or mobile detailing tools. Each of these uses requires slightly different foam properties depending on water pressure, cleaning technique, and environmental exposure.

- Automated Washes

- Manual Brushes

- Bus/Truck Wash

- Boat Cleaning

- SelfService Kits

- Mobile Detailing

4. Benefits of Using Quality Foam

Using highquality foam in car wash brushes offers several clear advantages. First and foremost, it protects the vehicle’s surface by reducing the risk of microscratches. Soft foam absorbs grit and dirt while minimizing friction. Second, these foams help improve the washing process by holding more soap and water, reducing the need for frequent reapplications.

Durability is another benefit; quality foam resists tearing and does not degrade quickly from repeated chemical exposure. It also ensures quiet operation in automated systems by absorbing vibration and reducing motor wear. In addition, foam is lightweight, reducing energy consumption in motorized brushes.

From a customer perspective, the use of gentle, effective foam results in cleaner vehicles and increased confidence in the washing process. Maintenance teams also benefit from longerlasting parts that require fewer replacements.

- Scratch Prevention

- Better Lather

- Chemical Resistance

- Reduced Wear

- Lower Noise

- Customer Satisfaction

5. Considerations for Foam Selection

Selecting the right car wash brush foam involves balancing softness, durability, and cost. A foam that is too soft may wear out quickly, while one that’s too firm could damage paint. The foam’s density and structure must match the specific machine’s speed and pressure.

Environmental factors should also be considered. Foams exposed to sunlight or extreme temperatures may need UVresistant or temperaturestable formulations. Equipment size and design influence the shape and thickness of foam inserts or strips.

Colorfastness is another factor, especially in systems where aesthetics matter or where colored foam may bleed under highpressure washing. Maintenance and replacement cycles should also be planned depending on the frequency of use and type of detergents applied.

Testing foam samples in realworld conditions is recommended before largescale deployment to ensure performance and compatibility with the entire washing system.

- Softness Balance

- Machine Fit

- UV Resistance

- Temperature Tolerance

- Color Stability

- Lifecycle Cost

6. FAQs about Car Wash Brush Foam

Q1: Will this foam scratch my car?

A1: No, car wash brush foam is designed to be soft and paintsafe.

Q2: How long does the foam last?

A2: With regular use, it can last several months depending on machine type and chemicals used.

Q3: Can it be used in manual car washes too?

A3: Yes, the same foam is often used in hand brushes and detailing tools.