Foam gaskets are flexible sealing components made from various foam materials such as polyurethane, polyethylene, neoprene, or silicone. Their primary role is to fill gaps between two surfaces, preventing the passage of air, water, dust, or other substances. Unlike traditional rubber gaskets, foam gaskets offer a lightweight, compressible, and costeffective sealing solution for low to moderate pressure applications. They’re widely used in industries like electronics, HVAC, automotive, construction, and medical devices.

These gaskets come in many forms—strips, sheets, rolls, or custom diecut shapes—and can include adhesive backing for easy installation. Depending on the foam type and cell structure (opencell or closedcell), foam gaskets can provide varying levels of resistance to moisture, temperature, vibration, and chemicals. The choice of foam depends heavily on the operational environment and required durability.

2. Materials and Properties

Foam gaskets can be made from a wide variety of materials, each with its own set of strengths and limitations. Polyurethane foam is soft, lightweight, and ideal for general cushioning and indoor applications. Polyethylene foam is denser, waterresistant, and suitable for packaging and sealing outdoor equipment. Neoprene and EPDM foams are preferred for their resistance to oils, ozone, and weather, making them ideal for harsh environments. Silicone foam, while more expensive, offers outstanding thermal and UV resistance and is used in highperformance or hightemperature applications.

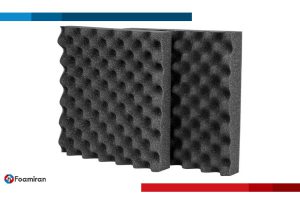

The properties of the gasket—such as compression recovery, density, and cell structure—directly affect its sealing ability and lifespan. Opencell foams allow air to pass through and are more compressible, while closedcell foams are more water and airresistant. Selecting the right material ensures optimal performance and minimal maintenance or failure.

- Polyurethane Foam

- Polyethylene Foam

- Neoprene Foam

- Silicone Foam

- OpenCell Form

- ClosedCell Form

3. Design and Manufacturing

The design of a foam gasket depends on its application. Key considerations include shape, thickness, compression range, and required sealing force. Gaskets can be produced through diecutting, CNC routing, waterjet cutting, or laser cutting—each offering different levels of precision and production volume capabilities. Lamination is also common, especially when combining layers of foam or adding adhesive backings.

Adhesivebacked foam gaskets simplify installation, particularly in mass production settings where time and consistency are critical. The adhesive must be compatible with both the foam material and the surface it’s being applied to. Tolerances must also be considered—especially in mechanical assemblies—since overcompression or poor fit can compromise gasket function.

Design validation and prototype testing are crucial stages in development, especially for custom gaskets used in highstakes or regulated environments like electronics or medical devices.

Shape Precision

Compression Tolerance

Cutting Methods

Lamination Options

Adhesive Backing

Prototype Testing

4. Applications Across Industries

Foam gaskets are used in nearly every sector that requires sealing, damping, or cushioning. In the automotive industry, they’re used in doors, lighting enclosures, dashboards, and HVAC systems for vibration damping and air sealing. Electronics use foam gaskets in displays, speaker enclosures, and battery compartments to block dust and moisture while absorbing vibration. In HVAC systems, foam gaskets prevent air leaks and ensure efficient airflow.

Construction applications include window and door seals, where foam helps in insulation and weatherproofing. In medical devices, they are used for hygiene seals, cushioning, and disposable components in diagnostic equipment. Packaging uses foam gaskets for sensitive product protection, especially in shockprone transit environments.

Each application depends on a combination of sealing effectiveness, environmental resistance, cost, and ease of installation.

- Automotive Seals

- Electronics Gaskets

- HVAC Components

- Construction Use

- Medical Devices

- Protective Packaging

5. Advantages and Limitations

Foam gaskets offer a number of advantages that make them a goto solution in many applications. They’re lightweight, compressible, and easy to install. Their flexibility allows them to conform to irregular surfaces, providing an effective seal even where tolerances aren’t perfect. Many foam types are also resistant to temperature changes, UV light, and chemical exposure. Costwise, they are typically more affordable than solid rubber or metal gaskets, especially in largevolume production.

However, foam gaskets are not without limitations. They may not withstand very high pressures or extreme chemical environments. Overcompression or exposure to harsh conditions can reduce their lifespan. The selection of the wrong foam type may lead to rapid degradation, leakage, or performance loss. For critical sealing needs, additional design reinforcement or alternative materials may be necessary.

- Lightweight Form

- Cost Efficiency

- Easy Installation

- Moderate Durability

- Limited Pressure

- ApplicationSpecific

6. FAQs About Foam Gaskets

Q1: What’s the difference between opencell and closedcell foam gaskets?

A1: Opencell foam is more breathable and compressible, while closedcell foam resists moisture and air better.

Q2: Are foam gaskets reusable?

A2: Generally no. Most foam gaskets are designed for singleuse, especially if compressed or exposed to harsh conditions.

Q3: Can foam gaskets be used outdoors?

A3: Yes, especially closedcell types like neoprene or EPDM, which are resistant to UV, ozone, and moisture.

Q4: Are adhesive foam gaskets reliable for longterm use?

A4: Yes, if the adhesive is chosen properly for the surface and environment.