What exactly is the difference between closed-cell and open-cell foam?

Foams are the backbone of many everyday products; from closed-cell foam flooring in sports halls to protective packaging, wall coverings, and underlayments. The main difference comes down to the cellular structure: in closed-cell foam, the cells are separated and impermeable; but in open-cell foam, the cells are interconnected and permeable to air and water.

This small difference creates huge results in water absorption, thermal insulation, durability, and shock absorption.

What is closed-cell foam?

Closed-cell foam has a compact structure; this causes it to:

- Be up to 98% waterproof and moisture hardly enters the texture.

- Be a very good shock absorber (Prime example: EVA foam).

- Provide high-efficiency thermal and sound insulation.

- Show good stability against UV and chemicals.

- Have a longer lifespan (10 to 15 years depending on usage conditions).

A well-known example of this group is Foamiran’s EVA foam, which is produced with a density range of 30 to 180 kg/m³ and customized for a wide range of needs—from light packaging to industrial shock absorption.

Important applications of closed-cell foam

- Sports flooring and children’s rooms (safety, hygiene, easy cleaning)

- Industrial and automotive shock absorbers (shock and vibration absorption)

- Protective packaging for sensitive equipment

- Sound and thermal insulation in buildings (wall covering, underlayment)

- Insoles and outsoles for professional shoes

What is open-cell foam?

In open-cell foam, cells are connected, and air/water moves easily through the texture. The result of this feature:

- More softness and comfort (up to 30% softer than closed type), suitable for furniture and cushions.

- Higher water and moisture absorption; not ideal for humid environments.

- Weaker thermal insulation (up to 2x more heat transfer compared to closed type).

- Less durability (usually under 5 years in high-pressure uses).

10 fascinating facts about closed-cell and open-cell foam

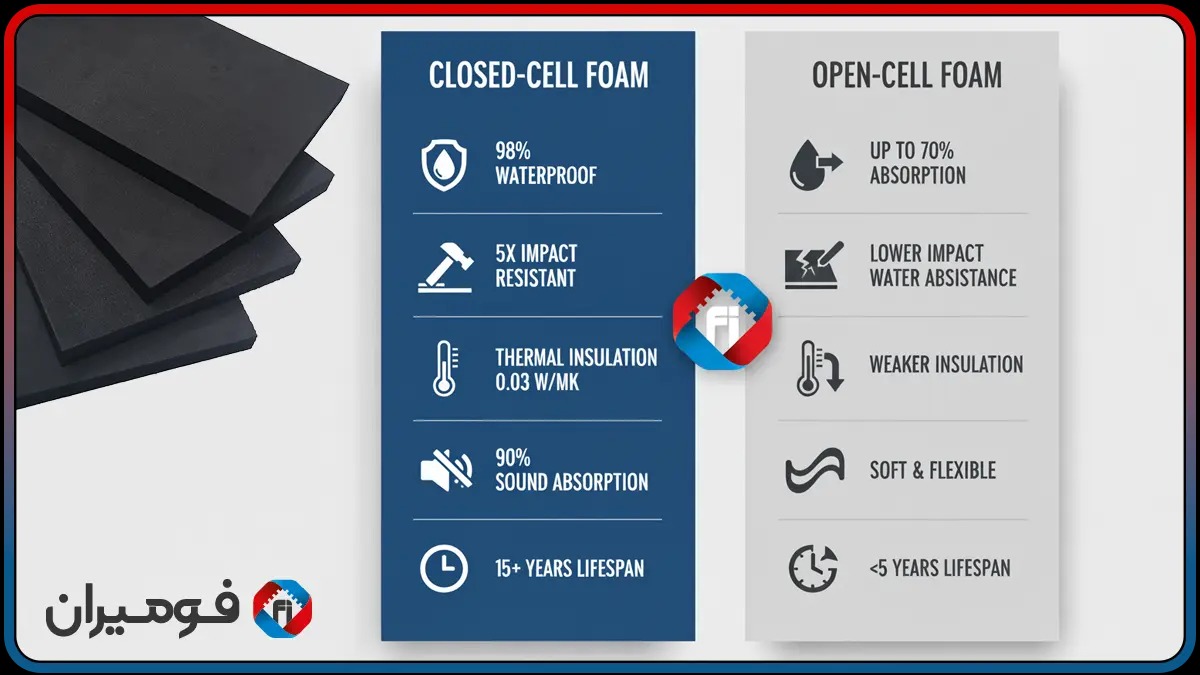

- Closed-cell foams are up to 98% waterproof; open-cell may absorb water up to 70% of its volume.

- EVA foam has up to 5 times more impact resistance than open-cell foam.

- The heat transfer coefficient of closed-cell is about 0.03 W/mK; open-cell performs up to 2 times weaker.

- EVA foam density at Foamiran is adjustable between 30 to 180 kg/m³ (from light to heavy).

- Open-cell foams are about 30% softer than the closed type, but have less durability and strength.

- The lifespan of closed-cell foam can reach 15 years+; open-cell foam usually < 5 years.

- EVA foam provides up to about 90% sound insulation in some applications (wall covering, underlayment, studio).

- The global market value of EVA is estimated to exceed 12 billion dollars by 2030.

- EVA recyclability in specific industrial processes is achievable up to about 70%.

- In water absorption tests, open-cell absorbs water up to 50% of its weight within 1 minute; closed-cell remains under 5% even after 24 hours.

Why is EVA foam the best representative of closed-cell foams?

EVA foam offers a unique combination of flexibility, resilience, waterproofing, shock absorption, and environmental stability. That is why it is very popular in EVA foam applications in packaging sensitive goods, making sports shoe insoles and outsoles, the best closed-cell foam flooring for halls, as well as in wall coverings and underlayments.

When to choose which foam?

- Humid spaces/in contact with water: Closed-cell (EVA) due to very low water absorption.

- Industrial or sports shock absorber: Closed-cell; up to 5x better impact resistance.

- Strong thermal insulation: Closed-cell with λ≈0.03 W/m·K.

- Soft comfort for seating/furniture: Open-cell (higher softness; watch out for humidity).

- High lifespan and low maintenance: Closed-cell (10–15 years+).

Important foam buying tips (quick and practical)

- Define the usage precisely: Humidity, impact, temperature, pressure, hygiene.

- Choose density and hardness correctly: From 30 to 180 kg/m³ for EVA depending on needs.

- Dimensions and cutting: Foamiran customization possibility reduces cost and waste.

- Standard and brand: Buy from a reputable manufacturer with quality and safety certificates.