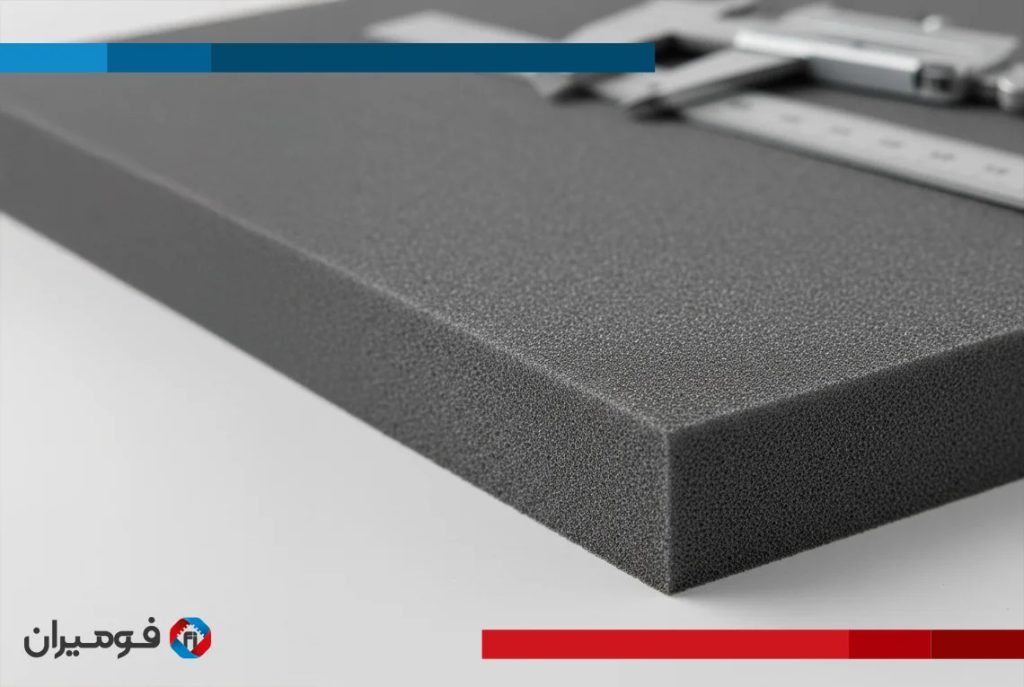

Compressed Foam is a type of closed-cell foam with high density, very low water absorption, and excellent resistance to heat, pressure, and chemicals. This foam has extensive applications in construction, automotive, and industrial packaging industries, and with its capability for cutting, laminating, and custom production, it is considered a professional choice for engineering projects.

Compressed Foam is a family of engineering foams with a closed-cell structure and high density, primarily produced based on LDPE/PE and in some grades combined with EVA. The result is a material with excellent dimensional stability, load-bearing capacity, thermal/acoustic insulation, and chemical resistance; suitable for industrial underlays, automotive shock absorbers, packaging of sensitive equipment, and building insulation.

History, Background, and Foamiran’s Leadership in the Middle East

Foamiran began its activities in the early 2000s with the aim of localizing the knowledge of engineering foam production and creating a complete value chain from raw materials to the final product. Strategic focus on developing controlled foaming technologies, investment in advanced lines, and the establishment of ISO 9001 / 14001 / 45001 management systems have turned Foamiran into the pioneer of the foam industry in Iran and the Middle East.

Over these years, by offering a wide range of closed-cell products (EVA, PE, Hard Foam, etc.), the company has met the needs of various industries—from construction and automotive to industrial packaging and electronic equipment—and is known for precise customization (density, hardness, thickness, lamination, and color) for specific projects.

Foamiran’s position is not merely the result of production capacity; the application engineering network, quality control laboratories, and close collaboration with customers’ R&D units have made this brand the reference for foam selection in projects with high technical sensitivity. Today, Foamiran products, in addition to the domestic market, are recognized in regional markets as standard and durable examples for harsh climatic conditions; from the scorching heat of southern regions to the severe cold of mountainous areas. It is this field experience and supply stability that has turned Foamiran into a leading name in the Middle East.

Why Foamiran Compressed Foam? Engineering and Economic Advantages

- Load and Impact Bearing: High densities (up to 380 kg/m³) and hardness of 50–75 Shore C are ideal for underlays and shock-absorbing pads.

- Closed-Cell and Low Absorption: Water absorption less than 5%; suitable for humid spaces, cold storages, and outdoor environments.

- Chemical Resistance: Stability against acids, bases, alcohols, fuels and oils, and many organic solvents.

- Thermal Performance: Reliable operation from -40 to +70 °C (short-term tolerance up to ~110 °C depending on the grade).

- Processing and Customization: Precision cutting, die-cutting, CNC, multi-layer lamination, adhesive backing, logo printing/engraving, and corporate color production.

- Economic Efficiency: Excellent strength-to-weight ratio, lighter installation and transport compared to hard alternative parts, and long service life.

Applications by Industry

Construction and Infrastructure

Thermal and acoustic insulation in floors/walls/ceilings, industrial floor underlayment, sealing strips and vibration dampers, underlayment for cold storages and clean rooms.

Automotive and Transportation

Shock-absorbing pads and vibration isolators, cabin acoustic insulation (roof/door/dashboard), protection for sensitive modules, liners and spacers for CKD part packaging.

Industrial Packaging and Precision Equipment

Protective inserts (Foam Insert) for shock absorption, professional bags and cases, covers for laboratory/medical equipment—with dust-free surfaces for anodized parts.

Electric and Electronics

Electrical/thermal insulation, separation and short-circuit prevention, localized thermal management, and protection during transport of precision instruments.

Outdoors, Sports, and Special Uses

Gym underlayment and outdoor flooring (stability against UV and moisture), shock absorbers for military equipment and cases, buoyancy and fixturing for special projects.

Technical Specifications (Technical Data)

The CEO of Foamiran believes that competition in the foam industry today is defined more than ever by agile engineering and assurance of stable quality. For this reason, the design, production, and quality control loops at Foamiran operate seamlessly: from raw material selection and formulation optimization to precise adjustment of foaming profiles and periodic tests according to international standards.

Jahangiri says: “When an industrial customer asks us for compressed foam, they usually don’t just want a sheet or a block; they want a solution. A solution that withstands impact, temperature, moisture, and chemicals and can be processed on their assembly line without hassle.” To this end, Foamiran’s technical team prepares trial versions with different densities and hardnesses before mass production to select the optimal combination under real conditions. The result of this approach is lifecycle cost reduction for the client and assurance of supply stability in long-term projects.

From the perspective of senior management, “being a leader in the Middle East” does not just mean production capacity. By developing customization services (multi-layer lamination, adhesive backing, precision CNC cutting, logo printing/engraving, corporate color production) and establishing a direct communication channel with customers’ R&D units, Foamiran has been able to play the role of a technological partner rather than just a supplier. This close collaboration ensures that the final product is produced exactly according to the drawing and project requirements while maintaining reproducibility and quality traceability.

In conclusion, Jahangiri emphasizes: “For us, every custom order is an engineering commitment. From the moment specifications are received until the production series is delivered, the production, quality control, and support teams stand by the customer. This is the same philosophy that has turned Foamiran into the reference brand for engineering foams in Iran and the region over the past two decades.”