Foamiran EPDM/NBR foam with its closed-cell structure and excellent thermal and chemical resistance is the best choice for automotive sealing foam in dashboards and interior parts. By absorbing vibration, reducing engine noise, providing stability against oil and gasoline, and offering long durability, this foam significantly increases assembly quality and cabin quietness. You feel the difference when the silence and cohesion of car parts are maintained even on rough roads. Foamiran, using advanced production technology and stage-by-stage quality control, offers foams designed according to global standards and the needs of automakers’ production lines. If you are looking for a combination of performance, durability, and industrial elegance, Foamiran EPDM/NBR foam is exactly the material that every professional automaker relies on.

Why is EPDM/NBR Foam Ideal for Automotive Sealing?

The combination of EPDM (resistant to heat, ozone, and UV) and NBR (resistant to oil and fuel) creates an engineering material that remains stable under harsh automotive working conditions. This automotive sealing foam, while maintaining flexibility at low temperatures, does not lose its structure at high temperatures either. The result is effective sealing in dashboards, door strips, HVAC paths, and engine compartments; without cracking in the cold and without softening in the heat. These features have made Foamiran one of the reputable suppliers of EPDM/NBR foams in domestic and international automaker production lines.

Specifications and Technical Dimensions of Automotive Sealing Foam (Automotive Grade)

Automotive and Industrial Applications of EPDM/NBR Sealing Foam

The application of automotive sealing foam is not limited to dashboards and doors; this multi-purpose foam is used in various industries. In automobiles, its main function is thermal, acoustic, and vibration insulation. In the HVAC industry, it is used to prevent energy loss. In electronic equipment, it serves as a sealant and vibration insulator. Due to its high resistance to water and steam, EPDM/NBR foam is also used in marine and military industries. This flexible, safe, and durable foam is an ideal option for any industry requiring sealing and insulation.

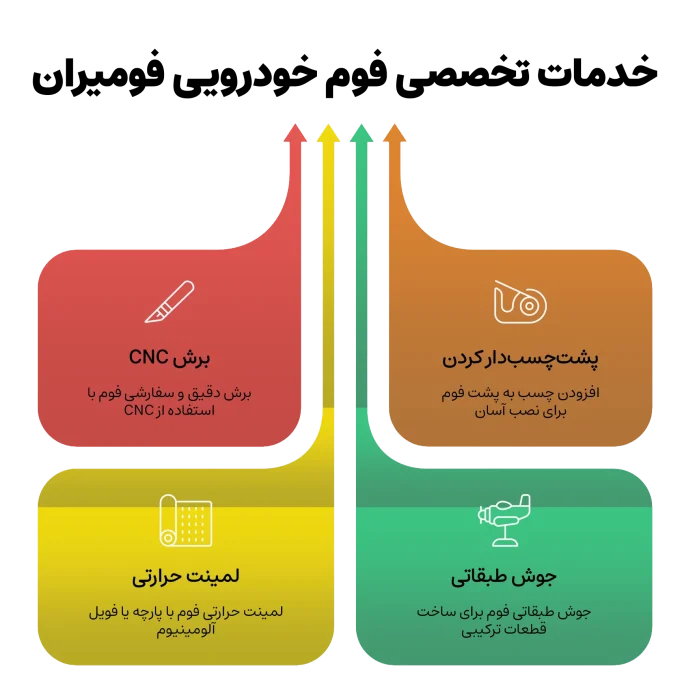

Services Applicable to Foamiran EPDM/NBR

In addition to producing raw materials, Foamiran Company offers specialized foam processing services to meet the precise needs of production lines. These services include precise CNC cutting and punching, adhesive backing of sheets, thermal lamination on fabric or aluminum foil, and layer welding for manufacturing composite parts. These capabilities have made Foamiran a supplier that supports the entire value chain of automotive foam, from design to installation.

Automotive Sealing Foam in the Path of Iran’s Industrial Development

The role of automotive sealing foam is not limited to just reducing noise and vibration; it is part of the process of upgrading national production quality. The use of engineering foams like EPDM/NBR in Iranian cars indicates the country’s automotive industry is moving towards global standards. By producing these specialized products and transferring closed-cell foam production technology, Foamiran has taken an effective step towards self-sufficiency in the automotive industry.

Optimizing Production Lines with Foamiran Automotive Sealing Foam

In the automotive industry, selecting the right foam is not only related to the final product quality but directly affects the efficiency and speed of production lines. Foamiran automotive sealing foam, with high cell uniformity and precise compression tolerance, makes the assembly process faster and more reliable. The excellent resilience property of EPDM/NBR ensures that there is no need for correction or re-cutting during the installation stages. On the other hand, the light weight and appropriate surface adhesion of the foam reduce the risk of detachment or slippage during parts pressing to zero. The result is waste reduction, increased production speed, and significant economic savings in automakers’ assembly lines.

Environmental Sustainability and Green Supply Cycle at Foamiran

Modern automakers are looking for materials that, in addition to technical performance, align with environmental principles. In this regard, Foamiran EPDM/NBR foam is designed using non-toxic raw materials, CFC-free, and recyclable. The production process of this foam at Foamiran is carried out in compliance with global ISO 14001 standards to minimize environmental impacts. Also, production waste re-enters the processing cycle, which reduces energy and raw material consumption. This sustainable approach has led to Foamiran being recognized as a green and responsible supplier in the supply chain of domestic and international automakers.

Quality Control and Tests of Automotive Sealing Foam at Foamiran

In the automotive industry, ensuring the performance of the foam seal in real road conditions is of special importance. By establishing an independent quality control unit, Foamiran subjects every production batch of EPDM/NBR foam to compression, thermal, and chemical resistance tests. In the compression test, the resilience rate of the foam after withstanding 24 hours of continuous pressure is examined to ensure no permanent deformation occurs in the door or dashboard. The temperature test also includes temperature cycles from minus 40 to plus 100 degrees Celsius to measure the structural stability of the cells. Finally, resistance to gasoline and oil is checked to prevent foam degradation in the engine environment. The result of these tests is a foam that passes not only the standards of Iranian automakers but also international criteria.

Foamiran; Two Decades of Experience, Advanced Technology, and Custom Production for the Automotive Industry

From 2002 until today, Foamiran, relying on technical knowledge, expert workforce, and modern equipment, has been recognized as the largest foam manufacturer in Iran and the Middle East.

By utilizing equipped production lines, an active Research and Development (R&D) unit, and international certificates ISO 9001, ISO 14001, and ISO 45001, this complex has the capability to produce various industrial foams including EPDM/NBR tailored to the needs of the automotive industry.

From design and precise cutting to the production of custom adhesive-backed sheets and rolls, Foamiran has always been a reliable partner for domestic and international automakers.

Today, Foamiran not only supplies automotive sealing foam for reputable Iranian brands but is also known as an exporter of high-quality industrial products to regional countries.