Park flooring, often known as granular or rubber flooring, is the primary covering for playgrounds and open spaces. The main purpose of using this product is to create safety. When children run in the park or athletes train outdoors, the ground beneath their feet needs to be shock-absorbing so that they are not seriously injured if they fall. Due to their high resistance to sun and rain, these floorings are the first choice for roofless spaces. Below, we examine the features and applications of this product.

What is granular flooring? (Same as compressed rubber)

Simply put: Granular flooring is the child of car tires! To make this product, worn-out car tires are shredded to turn into fine grains (granules). Then, these grains are mixed with very strong industrial adhesives and baked in special kilns under high pressure and heat.

The result is a heavy and incredibly tough rubber piece that won’t show any sign of wear even if it stays under the sun and rain for 10 years.

❓ What is the main difference between Granule and Tatami?

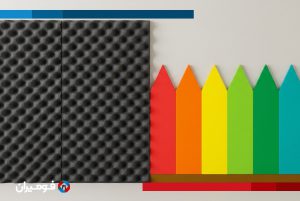

You might mistake these two for each other, but they have a big difference. Tatami is made of soft foam and is like a wrestling mat (specifically for indoor spaces and gyms). But Granule is made of hard rubber and acts like compressed gravel (specifically for outdoor spaces and parks). Tatami rots under the sun, but Granule loves the sun!

What exactly is park flooring made of?

As mentioned above, the raw materials of these floorings are rubber granule grains (shredded recycled tires) and special industrial adhesives. These materials are pressed under high pressure and heat. The result of this process is a product that is heavy and solid like stone, but has the elasticity of rubber.

Shock-absorbing structure

The rubber density in these floorings is high. This means that when a heavy object falls on it or a person falls down, the flooring compresses slightly and absorbs the impact intensity.

Water Passage (Drainage)

There are tiny pores between the granule grains, and grooves are designed underneath the flooring. Therefore, after rainfall, water does not stay on the surface and passes through underneath it.

Heavy and Stable

The weight of these pieces is high. This feature ensures that the floorings (especially in high thicknesses) remain fixed in their place and do not move easily.

Where are these floorings used?

In addition to parks, this product has other applications that may have received less attention:

- •Around pools: The granular surface has high friction and does not slip even when wet. It is suitable for preventing people from slipping around the pool.

- •Gyms: In the free weights section, where dumbbells and barbells fall on the ground, flooring is needed that both protects the gym floor and absorbs sound.

- •School and kindergarten yards: Replacing rough asphalt with granular flooring ensures the safety of students’ recess.

Technical Specifications Table (For Comparison)

Knowing the technical specifications helps you choose the right thickness based on your needs. For example, greater thickness is used for parks and less thickness for home uses.

Pros and Cons of Granular Flooring

Like any other product, park floorings have their own advantages and disadvantages that you should know before buying:

Advantages

- ✔ High resistance: It does not deform or rot under direct sunlight or snow and frost.

- ✔ Easy replacement: If one piece is damaged, there is no need to dig up the entire ground; only that single piece is replaced.

- ✔ Color variety: It is produced in ocher, jade, gray colors, etc., which is suitable for park design.

Disadvantages

- ✖ Surface roughness: The surface of this flooring is a bit rough and coarse for the indoor environment of the house (not suitable for bedrooms).

- ✖ Heavy weight: Moving packages of this flooring is a bit hard due to the high weight of the rubber.