Foamiran's Industrial Foam Components are precise solutions for sealing, sound and thermal insulation, and shock absorption in your production lines. These components are produced from engineered foams such as EPDM, EVA, PE, and Silicone/Neoprene through processes like die-cutting, CNC cutting, waterjet, and thermoforming. To view specifications and place custom orders, visit the Industrial Foam Components product page. Foamiran holds ISO 9001:2015, OHSAS 18001, and ISO 14001 certifications, guaranteeing quality, safety, and environmental care at all stages.

What Are Industrial Foam Components and Why Are They Vital in Product Design?

Industrial Foam Components are not just fillers; they are functional components that determine the final product quality by acting as seals, sound/thermal insulators, shock absorbers, and separators. The closed-cell structure of many of these foams ensures that water and dust penetration is minimized, making Industrial Foam Components the primary choice for washers, sealing strips, and sensitive gaskets. Furthermore, the elastomeric behavior dampens impact energy and prevents premature assembly failure.

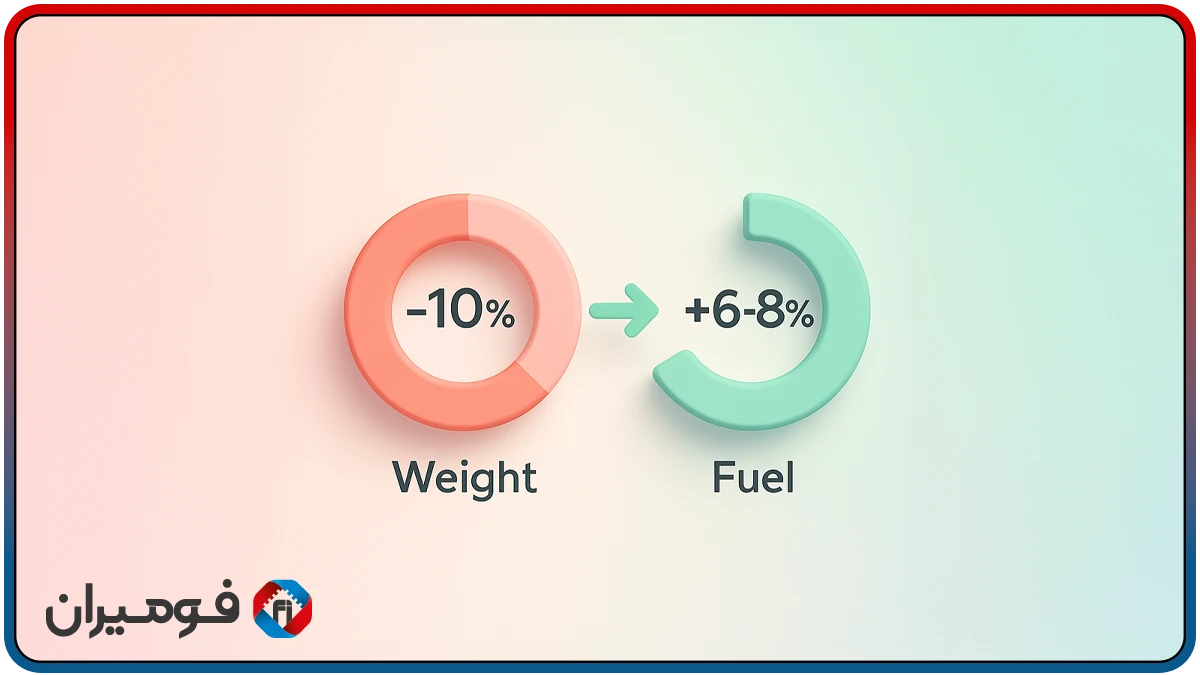

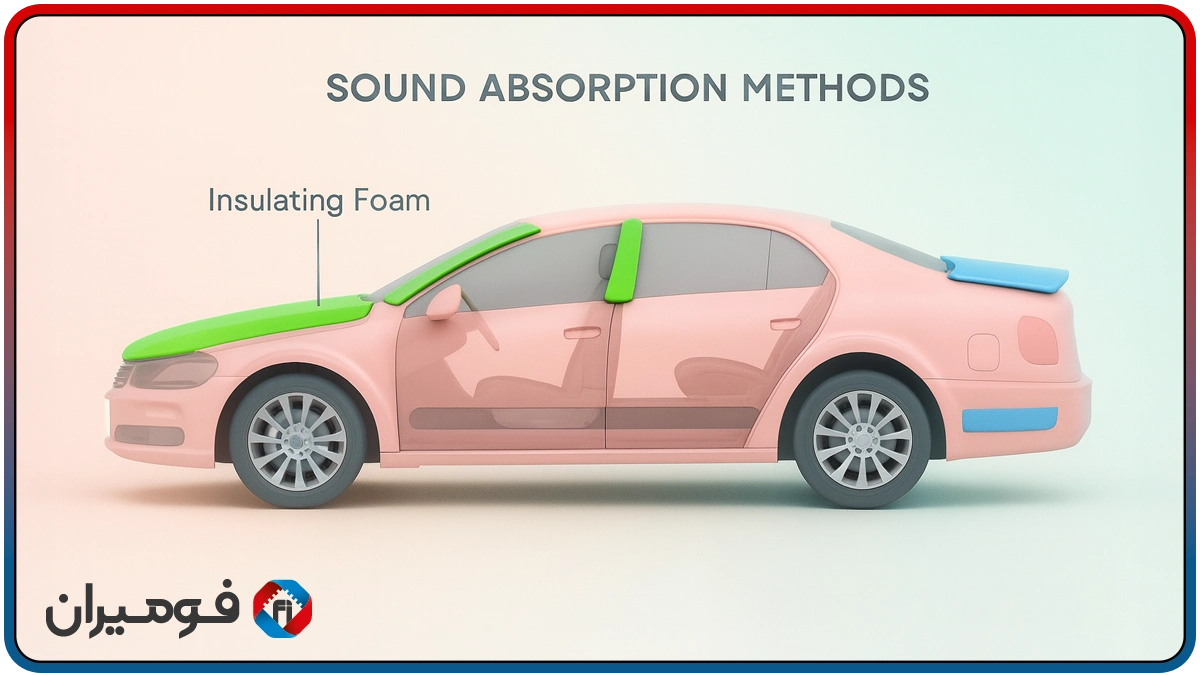

In automotive NVH systems, noise and vibration reduction is achieved with the help of Industrial Foam Components with engineered density and hardness. In electronic equipment, these same foam components act as spacers, protective pads, and anti-dust gaskets to simplify assembly while providing mechanical protection. At the same time, the very low weight of Industrial Foam Components facilitates energy consumption optimization in the final product.

With every 10% reduction in vehicle weight, fuel efficiency improves by 6 to 8%; the role of Foamiran's lightweight foam components in this improvement is key.

Advantages and Key Features of Foamiran's Industrial Foam Components

Relying on material and process knowledge, Foamiran offers a set of key features in Industrial Foam Components: shock absorption and vibration damping, complete sealing against liquids and dust, sound and thermal insulation, diverse coloring, the possibility of being adhesive-backed and laminated in multiple layers, reforming/shaping, and production in various dimensions and thicknesses. The existence of management systems ISO 9001:2015, OHSAS 18001, and ISO 14001 at Foamiran guarantees quality consistency and process traceability for this category of components.

Material Selection for Industrial Foam Components: EPDM, EVA, PE, and Silicone/Neoprene

Selecting the right material guarantees the function and durability of Industrial Foam Components. EPDM is unrivaled for harsh weather conditions, *UV* radiation, and severe temperature changes, making outdoor seals/washers long-lasting. EVA excels when softness and shock absorption are priorities—from protective pads to shoe components. Closed-cell PE, with negligible water absorption and chemical resistance, is ideal for waterproof packaging and pipe insulation. For special conditions like contact with oil or extremely high temperatures, Neoprene and Silicone are considered specialized options.

In high-risk shock absorption projects, using a GEL combination with EVA can significantly increase energy absorption. This solution creates a tangible performance difference in Industrial Foam Components for sensitive equipment packaging or industrial protective pads.

Production Processes of Industrial Foam Components: From Prototyping to Mass Production

Foamiran shortens the path from idea to final part with a range of processes. In high volumes, die-cutting is the most economical and fastest method for producing uniform gaskets and washers. For complex designs and prototype development, CNC cutting provides dimensional accuracy and repeatability. When clean edges are needed in high thicknesses, waterjet gives the best result without burning or thermal distortion. For 3D parts and shaped liners, thermoforming is an effective choice; and finally, with lamination and adhesive application, multi-layer and *adhesive-backed* structures can be created for quick installation on the production line.

Industrial applications of foam industrial parts

In **automotive**, Industrial Foam Components are used as sealants, sealing strips, light gaskets, dashboard sound/thermal insulators, and NVH components to reduce vibration. The weight reduction of these components is directly correlated with increased fuel efficiency. In **Construction and Civil Engineering**, expansion joints, sealing strips, and gap fillers enable noise control and energy loss prevention. In **Electronics**, protective pads, anti-dust gaskets, spacers for sensitive parts, and ESD insulation increase assembly and transport security. In **Packaging**, protective holders for delicate goods minimize damage by relying on shock absorption and low weight. **Medical** and **Military** industries also utilize Industrial Foam Components for protective pads, orthotic components, and packaging of sensitive equipment.

Sample Specification Table and Technical Information of Industrial Foam Components

Why Is Foamiran Chosen for Producing Industrial Foam Components?

With a long history in the foam market and relying on a flexible production infrastructure, Foamiran has integrated the value chain of "Material Selection → Product Engineering → Prototyping → Mass Production → Quality Control". Our technical team is with you from the map review and working condition assessment stage to the final delivery of Industrial Foam Components. Compliance with international standards, variety of raw materials, and access to cutting and shaping technologies reduce project risk and shorten time-to-market. To start, visit the Industrial Foam Components page and contact us.