When it comes to equipping children’s play areas, parks, kindergartens, or even sports halls, two main factors always weigh in: safety for children and others, and cost-effectiveness. Project managers, municipalities, and business owners are always looking for a solution to get the best quality at the most reasonable price. But does the word “cheap” in today’s volatile market mean low quality? Or is there a way to achieve a top-tier product when buying park flooring by eliminating unnecessary costs? At Foamiran Industrial Factory, we believe that access to standard products is the right of all industries and consumers.

What is Park Flooring and the Importance of Choosing It

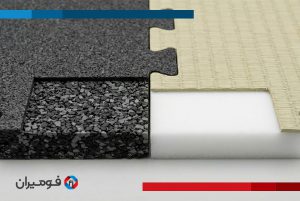

This product, often known as rubber flooring or outdoor Tatami flooring, is a protective layer installed on hard concrete or asphalt surfaces to reduce the impact of falls. In the foam manufacturing industry, raw materials speak first. For example, in the production of products that are the base of many soft and flexible Foamiran products, the percentage of material composition determines resilience. If low-quality recycled materials and poor adhesives are used in production, the final product might look the same as the original sample at first glance, but it quickly suffers from crumbling and discoloration under the sun’s UV rays.

This product, often known as rubber flooring or outdoor Tatami flooring, is a protective layer installed on hard concrete or asphalt surfaces to reduce the impact of falls. In the foam manufacturing industry, raw materials speak first. For example, in the production of products that are the base of many soft and flexible Foamiran products, the percentage of material composition determines resilience. If low-quality recycled materials and poor adhesives are used in production, the final product might look the same as the original sample at first glance, but it quickly suffers from crumbling and discoloration under the sun’s UV rays.

The importance of selecting the material type becomes clear here, knowing that every industry has its own specific needs. Just as materials used in military or medical industries require strict standards, park products must also have engineered “density” and “compaction”.

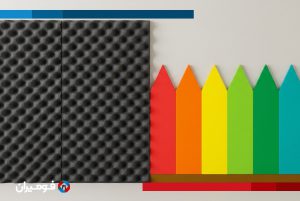

❓ What is the difference between Granular Flooring and Tatami?

When we talk about Foamiran products, there are two main categories. Granular flooring (Rubber Tiles) is formed from a mixture of rubber granules with polyurethane adhesives under high pressure, characterized by wear resistance and heaviness for outdoor spaces. In contrast, Tatamis are made of soft and flexible EVA, which are excellent for indoor spaces like kindergartens and have a hygienic and washable surface.

Technical Features of Foamiran Granular Flooring

Producing a high-quality granular flooring doesn’t end with just pressing rubber. At Foamiran, we have engineered the formulation of this product to have the highest durability in harsh weather conditions. Three key features that distinguish this product are:

High Density and No Peeling

Using German polyurethane adhesives and heavy thermal pressing ensures that the granule grains are completely interlocked. Unlike market samples, the surface of these floorings does not peel or become bald due to heavy foot traffic.

Water Drainage System (Drainage)

Channels and bases are designed underneath these floorings that allow rainwater and wash water to pass through. This feature prevents water accumulation, rotting under the flooring, and bad odors in parks.

Anti-UV Property and Color Stability

Foamiran granular floorings contain UV stabilizers. This means that even under direct summer sunlight, they retain their color and do not become dry and brittle like ordinary rubber.

Diverse Applications of Granular Floorings

Foamiran granular products are not just for parks due to their high durability and shock-absorbing properties. A wide range of environments requires such a resistant covering:

Foamiran granular products are not just for parks due to their high durability and shock-absorbing properties. A wide range of environments requires such a resistant covering:

- •Children’s play areas: Use in parks, kindergarten courtyards, and schools to prevent children from getting hurt while playing and running.

- •Gyms and free weight areas: Withstanding the heavy weight of gym equipment and preventing damage to the hall floor when dropping dumbbells and barbells.

- •Sidewalks: Creating a non-slip and safe surface for people to walk on, even in wet and rainy conditions.

- •Stables and livestock centers: Use as flooring under livestock to prevent joint damage to animals and for ease of cleaning.

HIC Safety Standard and Comparison Table

One of the most specialized topics in purchasing is the HIC or Head Injury Criterion standard. Cheap and non-standard products might seem soft but lack proper elasticity and return the impact energy to the child’s body. In the table below, we have made a comparison between Foamiran products and market samples:

Advantages of Direct Buying vs. Buying Through Intermediaries

Our article title was about buying cheap. But what is the secret to this cheapness? In the traditional market, the raw material broker, the manufacturing middleman, the wholesaler, and the installer each add a percentage to the price. Here we examine the advantages of buying directly from Foamiran versus the disadvantages of the open market:

Advantages of buying from Foamiran (Factory)

- ✔ Real Price: Eliminating all intermediaries means paying only for the finished product.

- ✔ Material Assurance: Buying a product with high purity percentage, not a product weighted down with stone powder.

- ✔ Customization: Possibility to order color, thickness, and hardness based on exact project needs.

Disadvantages of buying from intermediaries

- ✖ False Price: Unjustified price increase due to the product changing hands.

- ✖ Unknown Quality: Inability to trace raw materials and potential use of toxic waste.