Introduction

In the world of polymer materials, Elastic Foam or Resilient Foam is considered one of the most advanced generations of EVA foam. Due to its specific copolymer structure, this foam has a unique ability for instant return to its initial state after pressure and, while soft, possesses high strength and durability. The combination of contradictory properties—namely softness, hardness, and resistance—has turned it into an ideal option for medical, shoemaking, automotive, and industrial packaging industries. Furthermore, Elastic Foam is inherently waterproof and a suitable sound and heat insulator, offering a longer lifespan compared to ordinary foams.

What is Elastic Foam and How is it Made?

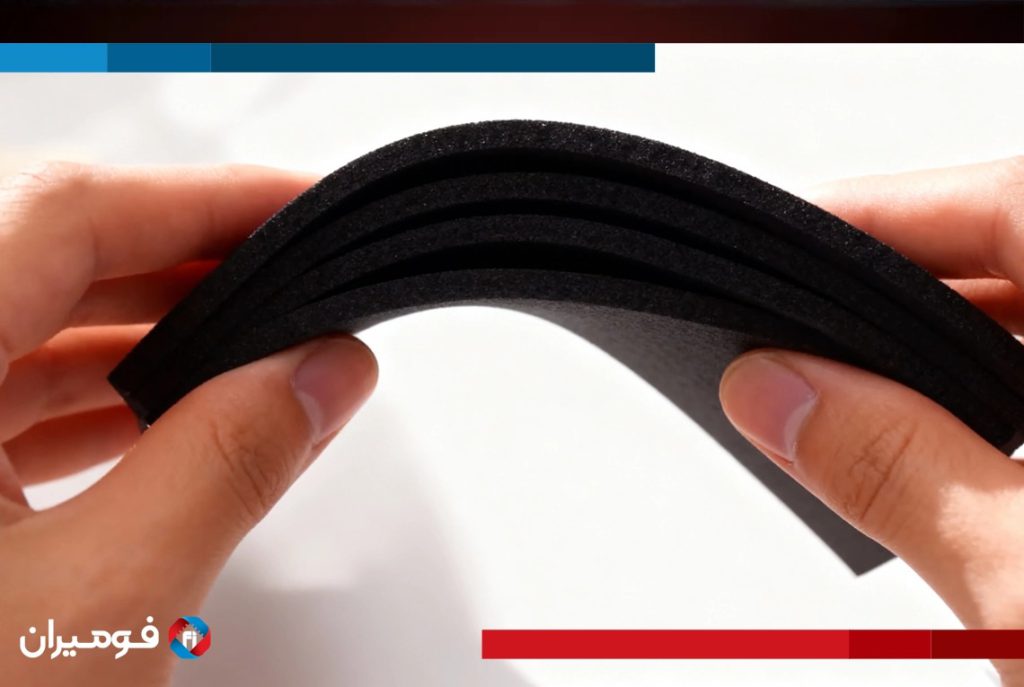

Elastic Foam, also known as Resilient EVA Foam, is made from Ethylene-Vinyl Acetate copolymer. The higher the Vinyl Acetate (VA) percentage, the softer and more flexible the foam; and the lower it is, the harder and more resistant the foam becomes. This very feature places Elastic Foam in the category of hard resilient foams; meaning a foam that returns to its initial state quickly and without permanent deformation after pressure.

In the production process, EVA granules are melted and combined with selected additives to form a closed-cell structure. Then, through controlled foaming, uniform cells are created throughout the sheet; a structure that is resistant to water penetration, mechanical shock, and temperature changes. Finally, the sheets, after quality control, are supplied as sheets, rolls, or custom parts based on the order.

Features of Elastic Foam (Resilient)

- Impact and Vibration Absorption Capability: Effective protection for the body and sensitive parts.

- Instant Rebound: Quick return to original shape without permanent deformation.

- Memory Foam: Temporary retention of shape followed by a soft return to the initial state.

- High Hardness and Mechanical Durability: Resistance against repeated compression and abrasion.

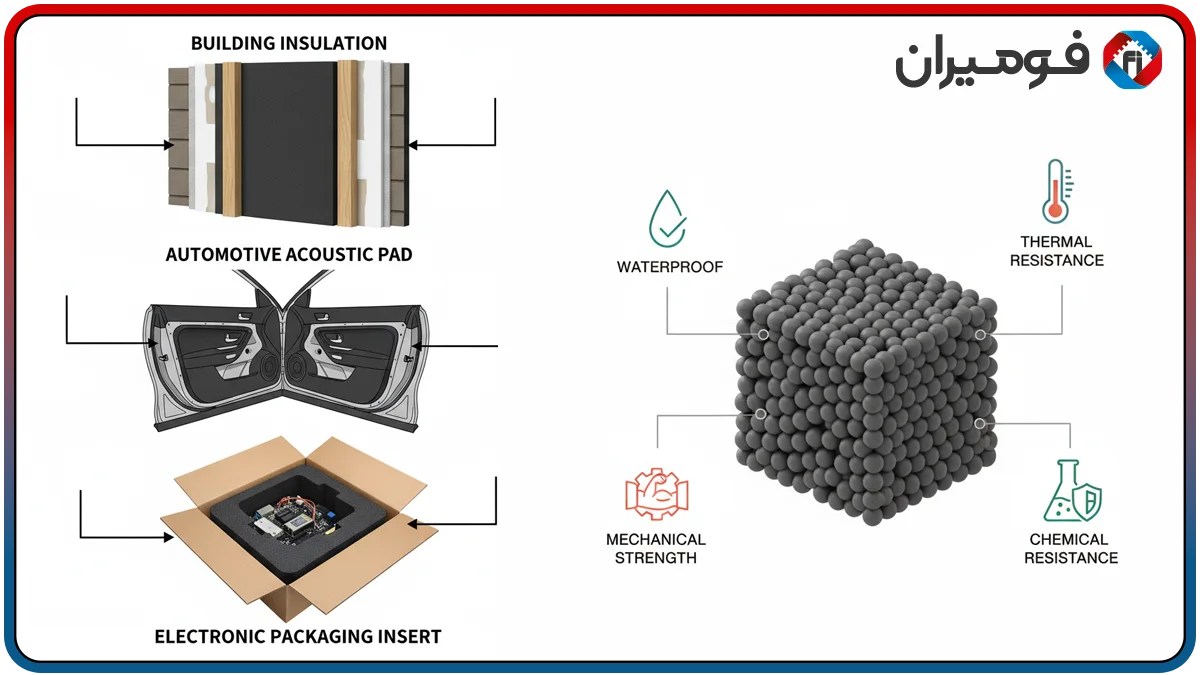

- Waterproof and Hygienic: Closed-cell structure, odorless, and resistant to fungal/bacterial growth.

- Sound and Thermal Insulation: Low acoustic and thermal conductivity for comfort and efficiency.

- Lightweight yet Resistant: Excellent strength-to-weight ratio.

- Stable Performance in Cold and Heat: Suitable for a wide range of climatic conditions.

Difference Between Elastic Foam, Compressed Foam, and Ordinary EVA Foam

All three belong to the EVA family; however, differences in density, hardness, and rebound cause noticeable differences in performance and application. Compressed foam is more suitable for bearing heavy loads and underlayment; Ordinary EVA foam is softer and lighter; and Elastic foam, positioned between the two with an excellent balance of flexibility and durability, is ideal for multi-purpose products.

Elastic Foam Production and Cutting Methods

Elastic foam is produced in a controlled foaming process to achieve uniform cells, stable density, and a clean surface. After production, depending on the application, cutting and processing are performed using the following methods:

- CNC: Precise parts with complex shapes; suitable for medical and precision packaging.

- Die-cutting: High volume and repetitive shapes such as insoles and vibration dampers.

- Thermal Cutting (Wire Cut): Clean and sealed edges for waterproof parts.

- Multi-layer Lamination: Combination with fabric/PU/leather/other foams for special applications.

- Adhesive Backing: Quick and clean installation in production lines.

Application of Elastic Foam (Resilient) in Various Industries

The closed-cell structure, rapid rebound, shock absorption, and high abrasion resistance make Elastic Foam ideal for the following areas:

Medical and Orthopedics

- Medical belts and collars, knee/wrist braces, orthopedic insoles and shoes.

- Shock-absorbing pads for beds and rehabilitation equipment.

- Suitable for latex-sensitive patients due to being waterproof and hypoallergenic.

Footwear and Sportswear

- Sports shoe soles and lightweight slippers with excellent shock absorption.

- Orthopedic insoles and anti-impact pads for long-term comfort.

- Sports guards (knee pads, elbow pads, shin guards).

Automotive

- Sound insulation and vibration damping in the cabin, roof, floor, and doors.

- Safety pads, component separators, and noise/vibration reduction.

- Safety pads, component separators, and noise/vibration reduction.

Industrial Packaging

- Protective inserts for sensitive parts and electronic equipment.

- Stability during transport and resistance to moisture and temperature.

Construction and Decoration

- Sound and thermal insulation in floors/walls/ceilings, and sealing and vibration-damping strips.

- Underlayment for industrial and commercial floors.

Sports and Safety Equipment

- Yoga mats, Tatami, and gym flooring with anti-slip properties.

- Headguards, shoulder, and chest pads for high-contact sports.

Handicrafts and Education

- Foam flowers, masks, crafts, and educational modeling; suitable for thermal molding.

Aquatic and Recreational Equipment

- Swimming boards, pull buoys, diving equipment, and water/snow ski boots.

Foamiran; A Leader in Quality, Technology, and Global Trust

Foamiran company, as the largest producer of EVA foam in the Middle East, with over two decades of experience and utilizing advanced production lines, has the capability to mass-produce various industrial, sports, and medical foams in diverse densities and thicknesses. Using modern equipment, a precise quality control system, and dedicated laboratories, this complex manufactures its products according to global standards.

Foamiran is proud to have received prestigious international certifications including ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and ISO 45001 (Occupational Health and Safety). These certificates demonstrate Foamiran’s commitment to quality, sustainability, and safety in all stages of production and collaboration with domestic and international industries.