The tempered glass carrying foam pad with a dual-layer EVA/PE structure and a T-layer is a safe solution for preventing scratches and breakage on vehicle assembly lines. These pads, by absorbing 85% of vibrations and being anti-slip, reduce damage costs by up to 30%. At Foamiran, custom products for laminated and tempered glass are produced with advanced technology to increase factory efficiency.

Why Does the Automotive Industry Need Tempered Glass Carrying Foam Pads?

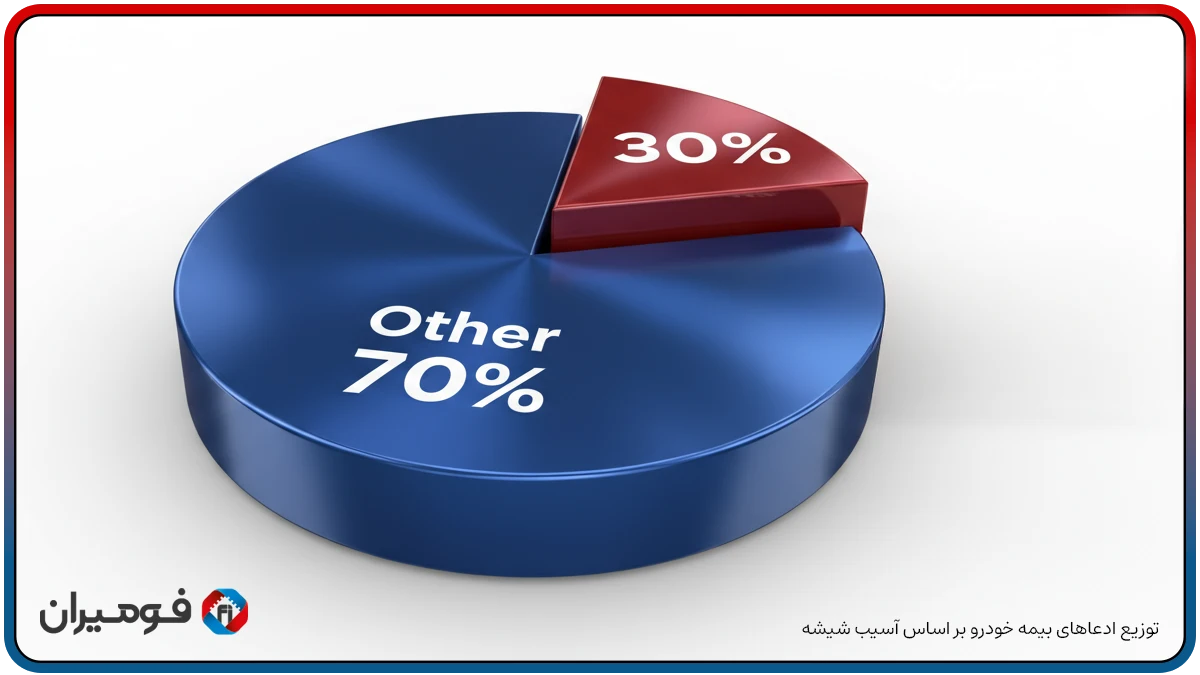

In vehicle assembly lines, transporting tempered and laminated glass is one of the main logistics challenges. These glasses, which are often curved and sensitive to point impacts, are moved in mobile racks or conveyor belts. Every small vibration can create invisible micro-cracks that later lead to sudden breakage. According to industry statistics, about 30% of car insurance claims are related to glass damage, a major part of which occurs during the internal transport stage of the factory. The tempered glass carrying foam pad minimizes this risk by creating a soft and shock-absorbing layer.

In addition to safety, the foam pad has economic benefits. In automotive factories like Iran Khodro or Saipa, line stoppage due to glass damage can cost millions of Tomans per hour. Foam pads maintain assembly speed by uniformly distributing pressure and preventing slippage. This product is ideal not only for windshields (laminated) but also for side and rear windows (tempered), where complex geometry requires precise protection.

Finally, considering global standards like ISO 16750-3 for vibration testing, the use of tempered glass carrying foam pads is mandatory. These pads, with closed-cell materials, absorb 10-50 Hz vibrations of the conveyor belt and prevent stress transmission to the glass, which increases the durability of the final product.

Materials and Design of Tempered Glass Carrying Foam Pads

The design of the tempered glass carrying foam pad is based on two main layers: a compressed EVA/PE core for structural stability and a soft T-layer for vibration damping. This combination provides dual protection that withstands the weight pressure of stacked glasses and eliminates sudden shocks.

- EVA/PE Core: Density 40-60 kg/m³, resistant to indentation under static load up to 200 kg; ideal for heavy racks.

- T-Layer: Closed-cell structure with 95% resilience, vibration absorption up to 85%; resistant to moisture and industrial oil.

- Optional Cover: Felt or laminated fabric to increase friction and prevent curved glass slippage.

- Custom Dimensions: CNC cutting to adapt to glass geometry, from 500×300 mm to 2-meter rolls.

- Additional Features: Non-toxic, environmentally friendly (ISO 14001), useful life of 100-200 transport cycles.

This design turns the tempered glass carrying foam pad into a multi-purpose tool that shows high efficiency in dynamic factory environments.

Choosing the Right Thickness and Dimensions of Foam Pads for Types of Car Glass

Choosing the thickness of the tempered glass carrying foam pad depends directly on the glass type and transport system. For laminated windshields, which are heavier (up to 30 kg) and larger, a total thickness of 12-16 mm (6-8 mm core + 6-8 mm T-layer) is recommended. This combination prevents local settling and keeps the rack weight balanced. In contrast, for tempered side windows, 8-12 mm is sufficient to maintain flexibility.

Dimensions are also key: 600×400 mm rectangular pads for standard racks, or curved shapes with 3D cutting for rear windows. At Foamiran, technical consultation is provided for precise calculation based on load and vibration frequency. For example, on conveyor lines with a speed of 1 m/s, a pad with 10 mm thickness can reduce vibration by 70%.

Furthermore, consider environmental factors like temperature (-20 to +80°C) and humidity. EVA materials in the tempered glass carrying foam pad have a thermal shrinkage of less than 1%, which guarantees dimensional stability.

Production and Installation Process of Tempered Glass Carrying Foam Pads at Foamiran

Since 2002, focusing on specialized foams, Foamiran has optimized the production process of tempered glass carrying foam pads with advanced second-phase machinery (2014). Production begins with raw EVA sheets: extrusion, T-layer lamination, and die-cutting or CNC cutting for ±0.5 mm precision. This method provides a monthly capacity of 1000 square meters and readies products for export to the Middle East.

Installing these pads on assembly lines is very easy. For fixed racks, heat-resistant acrylic adhesive backing up to 120°C is used, and in reusable systems, it is installed with bolts and nuts. At Foamiran, every pad undergoes a 24-hour pressure and vibration test to pass ISO 9001 standards. This approach not only guarantees quality but also enables customization for specific glass geometries (such as 30-degree curvature).

Relying on the R&D unit since 2010, Foamiran produces pads with 98% resilience that have less than 2% deformation after 200 cycles. This process has made Foamiran the largest foam manufacturer in Iran.

Foamiran: Trusted Partner for Supplying Tempered Glass Carrying Foam Pads

From its establishment in 2002 with 8500 square meters of land, Foamiran has become the largest foam manufacturer in Iran and the Middle East. With the first production phase in 2003 and the second phase in 2014, we have reached a capacity of thousands of square meters for EVA and T sheets. ISO 9001, 14001, and 45001 certificates, along with nanoscale, guarantee global quality. Our competitive advantage: 100% customization, export to various locations, and technical services like CNC cutting and lamination.

Cooperation with major automakers, such as supplying pads for Iran Khodro lines, demonstrates trust.