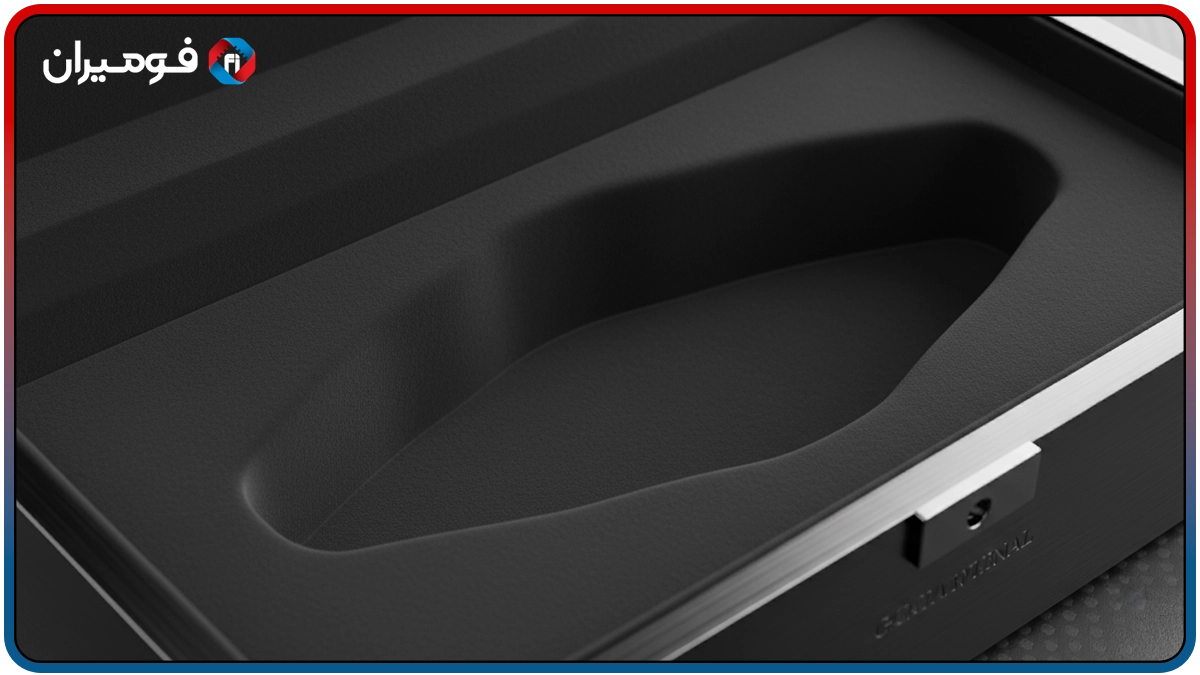

Glasses protective foam is one of the most important packaging components for protecting this sensitive instrument. Using glasses protective foam with a thickness of 4 to 8 mm, especially in glasses boxes and luxury accessories, can prevent damage and scratches caused by impact. In addition to providing excellent protection, these liners are customizable and can be designed precisely to fit the shape of glasses or other sensitive products. In this article, we will examine the features and applications of glasses protective foam and provide tips on selecting the best glasses protective foam for your products.

Why glasses protective foam?

Glasses protective foam for packaging boxes, due to its unique features, is one of the best choices for protecting glasses and accessories. These liners are specifically made of closed-cell foam which allows for shock absorption without deformation. Therefore, glasses or any other sensitive product inside the box are protected from risks caused by pressure and environmental impacts.

Furthermore, other features such as moisture resistance and easy cleaning have turned these liners into an ideal option for use in luxury and special packaging. Glasses protective foam with different thicknesses, from 4 to 8 mm, is used for various types of boxes and products and can be designed precisely and customized.

Guide to selecting the appropriate thickness of glasses protective foam

Selecting the appropriate thickness of glasses protective foam depends on packaging needs and the type of product sensitivity. Compressed foam sheets or semi-compressed ones with thicknesses of 4, 5, 6, 7, and 8 mm are used to select the best glasses protective foam. For delicate and sensitive glasses, glasses protective foam with less thickness (4 to 5 mm) is suitable, while for larger products or more resistant glasses, liners with greater thicknesses (6 to 8 mm) can be used.

Glasses protective foam with different thicknesses offers different protective capabilities. Since these foams are compressible, they can effectively absorb impacts and protect the product from damages caused by pressure and unwanted shocks.

Cutting and finishing methods of glasses protective foam

Glasses protective foam is easily cuttable using various cutting methods such as die-cut, CNC, and waterjet. These methods are particularly suitable for high precision and complex designs and allow for creating precise details. Additionally, glasses protective foam can be laminated with fabric or velvet as desired to give the glasses boxes a stylish and luxury appearance in addition to protective performance.

Using these methods and technical materials can lend a beautiful and modern appearance to glasses and accessory packaging and prevent potential damages. In addition to beauty, these foams have a long life and can easily endure under various weather and environmental conditions.

Impact and scratch test of glasses protective foam

Glasses protective foam, in addition to beauty and precision in design, must also have features such as resistance to impact and scratches. Closed-cell foam can absorb impacts well and prevent damage to the glasses. This feature is of great importance, especially in packaging boxes that are exposed to transportation and damages caused by impact.

To ensure the efficiency of glasses protective foam, impact and scratch tests are performed on it. These tests help ensure that the glasses protective foam protects the glasses well against external risks.

Customization of glasses protective foam and production volume

Glasses protective foam has high customizability. You can design glasses protective foam exactly according to the form of your glasses and also provide the possibility of adding details such as grooving for the hinge and bridge of the glasses. Furthermore, you can engrave your brand logo as emboss or cutout on the glasses protective foam so that your packaging gains a special effect.

These customizations can even be produced in large scales and different volumes, which allows brands to produce boxes with unique and attractive packaging. Glasses protective foam can also become adhesive-backed so that its installation inside the box becomes faster and easier.

Foamiran: Pioneering in the production of foam products and the path of development

Foamiran, with over two decades of experience in producing and processing foam products, is one of the pioneers of the foam industry in Iran and the Middle East. Using advanced technologies and specialized machinery, this company is capable of producing various types of glasses protective foam with different thicknesses, including glasses protective foam with thicknesses of 4–8 mm.

Foamiran specializes in the production of foam products and observes international standards in terms of quality. This company started its activity in 2002 and as the largest foam manufacturer in Iran, exports its products to over 20 countries. High production capacity and flexibility in foam product design have turned Foamiran into an ideal choice for brands looking for protective and stylish packaging.