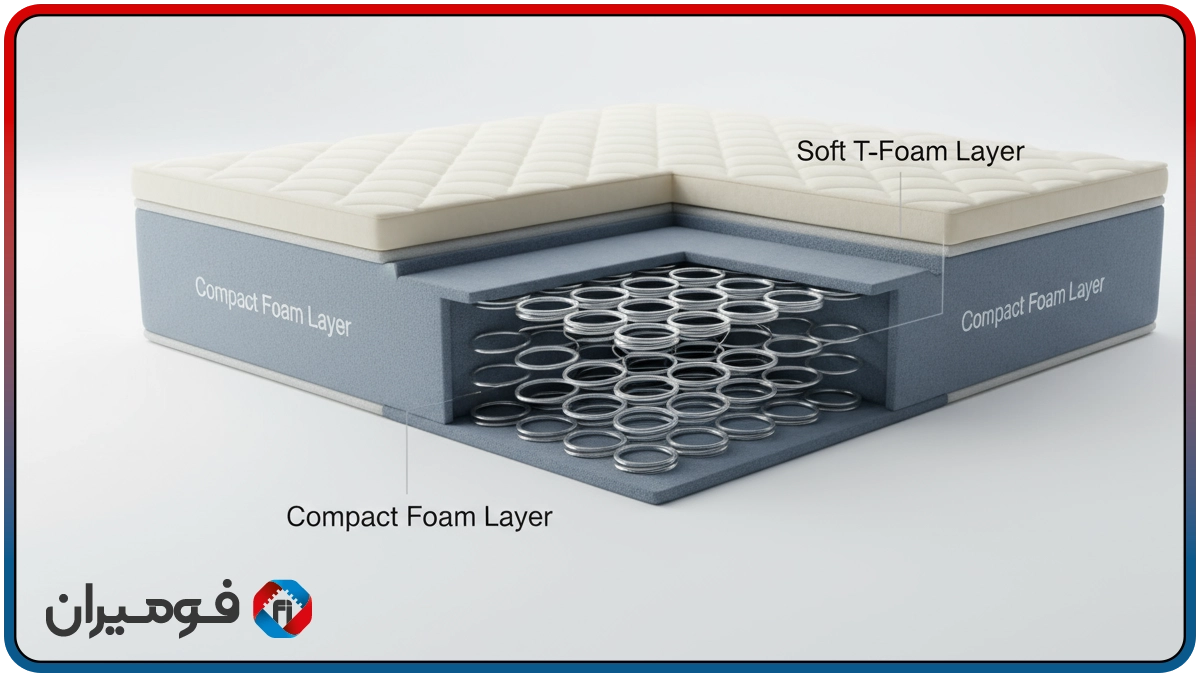

In the design of the spring mattress with compressed foam sheet and soft T layer, two key features—durability and comfort—are provided simultaneously. In this structure, the spring is enclosed between two layers of compressed foam to reduce noise and force transmission, and a layer of soft T foam is placed on top of it to provide a smooth and uniform surface for sleeping. The result is a silent mattress, with more resistant edges, stable form, and a feeling of long-term comfort.

What is the common problem with spring mattresses?

One of the common faults in traditional spring mattresses is the transmission of sound and vibration between the springs. These sounds are particularly annoying during quiet nights and eventually reduce sleep quality. Additionally, direct contact of fabric or sponge with the spring causes local sagging, deformation of the mattress, and shortening of its lifespan.

These challenges have been significantly resolved in Foamiran’s spring mattress with compressed foam sheet and soft T layer, and mattress manufacturers can provide greater durability and peace of mind with this method.

Foamiran Solution: Enclosing the spring with compressed foam sheet and soft T layer

In the construction of the spring mattress with compressed foam sheet and soft T layer, first, both sides of the spring cage are covered with a compressed foam sheet with a thickness of 3 to 6 mm. This harder layer distributes the shock and pressure of the springs uniformly and prevents the transmission of sound and movement to other parts of the mattress. Then, a layer of soft T foam with a thickness of 8 to 20 mm is placed on the surface to create comfort and a soft feeling in contact with the body. Finally, a fabric or laminated cover is added to achieve a beautiful appearance and greater durability.

Guide to selecting the appropriate thickness and hardness

The thickness of the compressed sheet is usually chosen between 3 to 6 mm; the higher the density and hardness of this foam, the better the noise control and edge stability will be. For the soft T layer, a thickness of 8 to 20 mm is determined based on the type of mattress (home or hotel). Softer mattresses use T foam with lower density to have a greater sense of comfort, while medical or hotel models use T foam with higher density for greater body support.

Advantages of using closed-cell foam in spring mattresses

The closed-cell feature in both foams—compressed and T—makes the mattress resistant to moisture, odor, and bacterial penetration. This structure does not allow air and liquids to pass through, and as a result, the mattress remains dry, clean, and durable. In addition, the high resilience and vibration absorption properties of the foams reduce body fatigue during long sleeps. Thus, the spring mattress with compressed foam sheet and soft T layer will not only be silent but also more comfortable and durable than common models.

Production Process and Quality Control

For manufacturing Foamiran’s engineered mattresses, foam cutting is performed with high precision according to the mattress core dimensions. In high circulation, cutting is done by die-cutting method, and in special projects, with CNC or waterjet machines so that the edges are clean and precise. If needed, the T foam layer is combined with fabric or sponge using the lamination method. Quality control includes point compression testing, pressure cycling, and fatigue testing to ensure the mattress retains its form and function after long-term use.

Health benefits of spring mattress with compressed foam and soft T layer

In today’s fast-paced world, sleep quality plays a vital role in maintaining individuals’ physical and mental health. Foamiran’s spring mattress with compressed foam sheet and soft T layer, beyond a simple product, is designed as an engineered solution to improve quality of life. By enclosing springs in layers of compressed foam, this structure minimizes vibration and noise, allowing the body to rest without disturbance throughout the night. The soft T layer, with high resilience, distributes pressure evenly and prevents pressure points on the spine, shoulders, and hips. This feature is particularly beneficial for people with back pain or orthopedic problems, as it provides proper support for the body’s natural curvature. Furthermore, the closed-cell foam used in these mattresses has high resistance to dust, mites, and bacteria, reducing the risk of allergies and respiratory problems. Studies show that sleeping on soft yet supportive surfaces lowers stress hormone levels and increases deep sleep (REM) quality. By focusing on health standards, Foamiran ensures that raw materials are free of harmful chemicals, making these mattresses a safe and healthy option for families, especially children and the elderly. Finally, the long-term durability of this product brings not only economic savings but also guarantees years of peaceful and healthy sleep by maintaining its original form. These benefits make the spring mattress a smart choice for those who value their health and seek a long-term investment in daily well-being. Using this technology, users have reported increased daily energy and better concentration in daily activities, which itself is a testament to the positive impact on overall health.

Maintenance tips and extending the life of spring mattress with compressed foam sheet and soft T layer

Proper maintenance of the spring mattress with compressed foam sheet and soft T layer is key to maximizing its benefits. First, it is recommended to place the mattress on a firm and flat base to avoid uneven pressure on the springs and maintain the overall form. Rotating the mattress once every three to six months evens out weight distribution and prevents premature sagging. For cleaning, use a vacuum cleaner with a soft brush to remove surface dust, but avoid direct washing with water because closed-cell foam does not absorb moisture and may cause mold accumulation. In case of staining, use mild and dry cleaners and allow it to dry completely. Also, using a waterproof protective cover extends the life of the soft T layer and prevents liquid penetration. Keep the bedroom temperature between 18 to 22 degrees Celsius so that foam materials retain their flexibility, and avoid excessive heat which can soften the structure. For families with pets, regular inspection to prevent damage from claws is essential. Foamiran suggests keeping the mattress away from direct sunlight to preserve the color and quality of materials. By observing these tips, the useful life of the mattress can reach up to 10 years or more, which not only reduces costs but also promotes environmental sustainability. Users who have followed these guidelines have reported that their mattress still offers initial comfort after years of use. Finally, an annual check-up by professionals can identify potential problems earlier and maximize product life, so investing in maintenance is a long-term return on investment in sleep quality and health.

Foamiran’s engineering and mass production capability

Foamiran, with over two decades of experience in producing EVA foam, compressed foam sheet, and T foam, is one of the leading manufacturers in Iran and the Middle East. Foamiran’s advanced cutting, punching, laminating, and adhesive lines enable custom production in various dimensions and hardnesses. Full compliance with ISO 9001, ISO 14001, and ISO 45001 standards guarantees the quality and durability of products at every stage of production.