EVA Foam – EVA Foam Roll & Sheet

Consulting and ordering

Order from the foamiran factory

What is EVA foam?

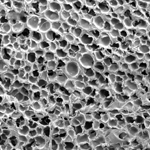

EVA foam (Ethylene-vinyl acetate) stands for ethylene-vinyl acetate closed cell copolymer foam and is one of the most widely used foams, which is known as a versatile foam. This foam is widely used in the automotive, packaging, bag and shoe, marine, cleaning, and sports product manufacturing industries and other industries.

Due to its closed cell structure, EVA foam provides several advantages, including rapid recovery of the foam after compression and flexibility, and helps to maintain its shape, in addition to shock absorption, thermal insulation, moisture resistance, buoyancy, and abrasion resistance. Chemicals are also another feature of this foam. As a UV-resistant and durable material, EVA foam is suitable for outdoor use in products such as surfboard pads, boat deck mats, and hot tub insulation.

EVA foam products

Technical Data

Click on the opposite link to download the technical information of EVA foam.

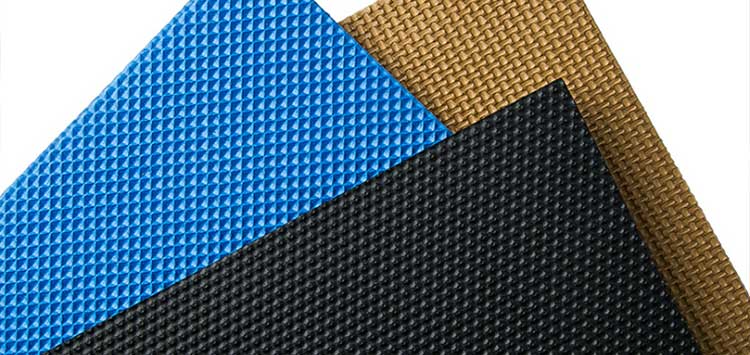

Types of EVA Foam Sheet

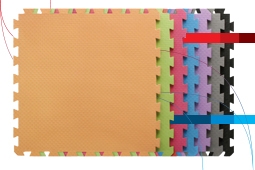

The various types of EVA foam sheets produced in the Foamiran facility are introduced in the following table, all of which have the capability of embossing. Different types of embossing, including plain, seven-pointed, eight-pointed, needle, chain, pencil, pleat, wave, honeycomb, ladder, window, almond, and other embossing patterns, can be created on these sheets.

| Sheet Name | Dimensions (cm) | Hardness | Color | Related Industries |

| Sheet EPVM-O1 | 180*120*3.0 210*125*3.0 240*140*3.0 | Regular, Semi-Compressed, Compressed, Microcell | Black | Stone washing, household and industrial uses, orthopedic industries, bag and shoe industries, special washer manufacturing, automotive industry, impact absorption |

| Sheet T10S-O1 | 240*140*3.0 | Regular, Semi-Compressed, Compressed, Microcell | Yellow, Orange, Red, Phosphorus, Tiffany, Light Blue | Stone washing, household and industrial uses, orthopedic industries, bag and shoe industries, special washer manufacturing, automotive industry, impact absorption, kindergarten |

| Sheet T40 (T Turk) | 210*125*3.0 185*125*3.0 | Regular, Semi-Compressed, Compressed, Microcell | Black | Stone washing, household and industrial uses, orthopedic industries, bag and shoe industries, special washer manufacturing, automotive industry, impact absorption, kindergarten |

| Sheet T42 | 200*130*3.1 220*140*3.0 | Regular, Semi-Compressed, Compressed, Microcell | Red, Blue, Yellow, Purple, Black, Gray, Tiffany | Stone washing, household and industrial uses, orthopedic industries, bag and shoe industries, special washer manufacturing, automotive industry, impact absorption, kindergarten |

| Sheet T45 | 180*120*3.0 100*70*2.0 145*90*3.0 215*125*3.0 | Regular, Semi-Compressed, Compressed, Microcell | Green, Black, Blue, Gray | Stone washing, household and industrial uses, orthopedic industries, bag and shoe industries, special washer manufacturing, automotive industry, impact absorption, kindergarten |

| Sheet T30S (Premium T) | 185*125*3.0 180*120*3.0 210*215*3.0 240*140*3.0 | Regular, Semi-Compressed, Compressed, Microcell | White, Black | Stone washing, household and industrial uses, orthopedic industries, bag and shoe industries, special washer manufacturing, automotive industry, impact absorption, kindergarten |

| Sheet P-7 | 225*135*2.9 250*150*3.0 | Regular, Semi-Compressed, Compressed, Microcell | Light Blue, Red, Phosphorus, Yellow, Pink, Purple, Tiffany, Black | Stone washing, household and industrial uses, orthopedic industries, bag and shoe industries, special washer manufacturing, automotive industry, impact absorption, kindergarten |

| Sheet P-37 | 240*140*3.0 240*140*3.5 | Regular, Semi-Compressed, Compressed, Microcell | Light Blue, Red, Phosphorus, Yellow, Pink, Purple, Tiffany, Black | Stone washing, household and industrial uses, orthopedic industries, bag and shoe industries, special washer manufacturing, automotive industry, impact absorption, kindergarten |

| Sheet P-47 | 240*140*3.5 160*110*3.0 350*150*5.0 | Regular, Semi-Compressed, Compressed, Microcell | White, Red, Yellow, Tiffany, Phosphorus, Blue | Stone washing, household and industrial uses, orthopedic industries, bag and shoe industries, special washer manufacturing, automotive industry, impact absorption, kindergarten |

| Sheet S-110 -O1 | 180*120*3.0 210*130*3.0 210*140*3.0 240*140*4.0 375*175*5.5 | Regular, Semi-Compressed, Compressed, Microcell | Yellow, Orange, Red, Phosphorus, Tiffany, Light Blue | Stone washing, household and industrial uses, orthopedic industries, bag and shoe industries, special washer manufacturing, automotive industry, impact absorption, kindergarten |

| Sheet RO5 | 375*170*5.5 240*140*3.0 210*125*3.0 | Regular, Semi-Compressed, Compressed, Microcell | The automotive industry, Washer manufacturing, Packaging industry, Lighting industry (bags and shoes), Impact protection production, Toy production, Construction industry for thermal insulation | The automotive industry, Washer manufacturing, Packaging industry, Lighting industry (bags and shoes) |

| Sheet D90-O2 | 210*125*3.0 240*140*3.0 | Regular, Semi-Compressed, Compressed, Microcell | White, Black, Blue, Red, Yellow, Phosphoric, Orange, Tiffany, Purple, Pink | The automotive industry, Washer manufacturing, Packaging industry, Lighting industry (bags and shoes), Impact protection production, Toy production, Construction industry for thermal insulation |

| Sheet D-95-O1 | 210*125*3.0 | Regular, Semi-Compressed, Compressed, Microcell | White, Black, Blue, Red, Yellow, Phosphoric, Orange, Tiffany, Purple, Pink | The automotive industry, Washer manufacturing, Packaging industry, Lighting industry (bags and shoes), Impact protection production, Toy production, Construction industry for thermal insulation |

| Sheet Ebtekar-7 | 370*170*5.0 | Regular, Semi-Compressed, Compressed, Microcell | Red, Blue, Yellow, Phosphoric, Black, Tiffany, Orange | The automotive industry, Washer manufacturing, Packaging industry, Lighting industry (bags and shoes), Impact protection production, Toy production, Construction industry for thermal insulation |

| Sheet Ebtekar-8 | 370*170*5.0 | Regular, Semi-Compressed, Compressed, Microcell | White, Black | The automotive industry, Washer manufacturing, Packaging industry, Lighting industry (bags and shoes), Impact protection production, Toy production, Construction industry for thermal insulation |

| Microcell Sheet (FO) | 170*100*3.0 140*90*2.0 | Microcell | White | Shoe industry |

| Sheet F-20 | 225*115*4.0 185*115*3.0 | Regular, Semi-Compressed, Compressed, Microcell | Black, Gray | The automotive industry, Washer manufacturing, Packaging industry, Lighting industry (bags and shoes), Impact protection production |

| Sheet F-30 | 240*140*3.5 | Regular, Semi-Compressed, Compressed | White, Botanic, Misty Rose, Golbahar, Yellow, Lemon Green, Yellow Green, Sea Green, Indigo, Orange, Tomato, Red, Barberry (Akrai), Coral, Indian Red, Fuchsia, Pink, Lavender, Purple, Turquoise, Deep Pink, Aqua Marine, Burgundy, Blue, Dark Salmon, Phosphoric, Cedary, Green, Blackberry, Coffee, Black, Gray | The automotive industry, Washer manufacturing, Packaging industry, Lighting industry (bags and shoes), Impact protection production, Toy production, Flower industry, Construction industry for thermal insulation |

| Sheet F-60 | 210*130*2.0 | Regular, Semi-Compressed, Compressed, Microcell | Black | The automotive industry, Washer manufacturing, Packaging industry, Lighting industry (bags and shoes), Impact protection production, Toy production, Flower industry, Construction industry for thermal insulation |

| Lightweight Polyethylene Sheet | 210*140*3.0 180*120*3.0 | Regular, Semi-Compressed, Compressed, Microcell | White, Gray, Black | Medical industry, Military industry, Bag and shoe industry, Construction industry for thermal insulation |

| Sheet SP | 180*120*3.0 210*125*3.0 210*140*3.0 210*215*3.0 180*120*3.0 | Regular, Semi-Compressed, Compressed, Microcell | Blue, Gray, Black, White, Red, Yellow, Green, Orange | Automotive industry, Washer manufacturing, Packaging industry, Lighting industry (bags and shoes), Impact protection production, Toy production, Construction industry for thermal insulation |

Properties of EVA foam

EVA foam product introduction video

Types of EVA foam

P group: a special group with softness, adhesion to the surface, and non-slip, very flexible and at the same time with proper reversibility. The presence of alpha-olefin in the ingredients of this category has made the foams of this category have a unique soft feeling. P group foams are used in various industries such as part of medical insoles, cleaning industries, shock absorbers, bags and shoes, etc.

T Group: Due to having EVA in their structure and unique formulation, this group of foams has excellent reversibility, high flexibility and the ability to be shaped by heat. Impact and buoyancy properties are also important properties in this category. T group foams are used in various industries such as automotive, construction, medicine and insulation, recreational and professional sports, adhesive tapes, shoes and packaging, shock absorbers, shock absorbers, and as buoys.

Polyethylene foam: PE foam is a durable, lightweight, flexible, and closed-cell material. It is often used for packaging industrial and agricultural goods due to its excellent vibration and insulation properties. It is also resistant to water, moisture, and chemicals, in addition, the effect of damping and absorption of vibration makes it very durable. PE’s thermal and sound insulation capabilities are also outstanding. It can also be molded, or molded to create a 3D structure. For high thicknesses, it can be laminated. Polyethylene closed cell foams are used in various industries such as automotive, construction, medical and insulation, recreational and professional sports, adhesive tapes, shoes, and packaging.

Recycled EVA foam: Recycled EVA foams are produced from light polyethylene, in which EVA is not used, for this reason, the material of these foams is drier and less reversible and flexible than sheets with EVA, which is why they are affordable. Recycled EVA’s closed cell foams are used in various industries such as automobile manufacturing, footwear, sports, packaging, bag and luggage manufacturing, and industrial parts suitable for each industry.

Applications of EVA foam

Due to the characteristics of elastic foam, it can be used in various industries, but in this section, most applications of foam in various industries are mentioned.

- The Automotive industry

- Packaging industry

- Making all kinds of shoes and bags such as laptop bags (shock absorbers)

- Medical industry (types of wristbands, knee braces, medical necklaces, and medical shoe soles)

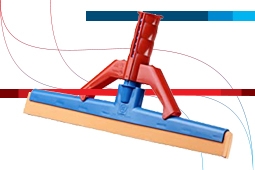

- Cleaning industry (glass washing, floor washing foams, etc.)

- Shipbuilding industry (ship bumper)

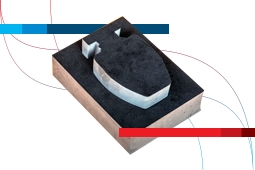

- Advertising industry (mouse pad, advertising hat)

- Construction industry (under carpet foam, silent parquet foam, and all types of sound and heat insulation foam)

Variety of EVA Foam Products

EVA foam is a type of closed-cell foam that is firmer than polyethylene. When you press down on it, it dips and then rises back up. EVA foam is a great product to use outdoors due to its durable construction and UV ray resistance. At Foamiran, we can produce and supply foam as layers, sheets, rolls, and custom-made pieces.EVA foam is a closed-cell foam that is firmer than polyethylene but still softer.

EVA Foam Products

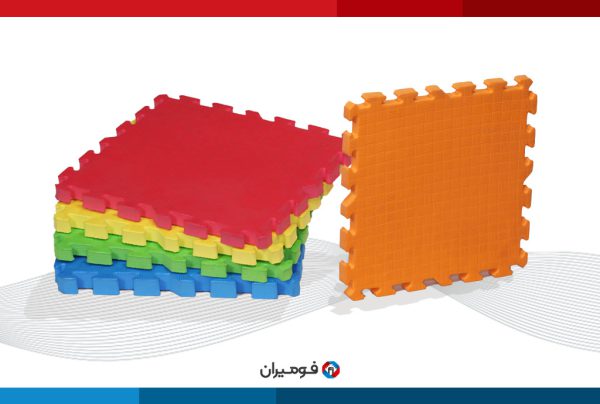

Foam puzzles are a top choice when it comes to brain games. Through these games, parents can help their children create beautiful designs.

Bags and shoes are made with foam that comes in a variety of colors and often have superior durability and strength. For instance, EVA foam, which is a type of foam known for its durability and lasting power, is used to make shoe soles, slippers, suitcase covers, and overlays. This foam is widely recognized as the top option in the market due to its attractive appearance, reasonable price, light weight, flexibility, and strength.

The high strength and softness of EVA foam make it ideal for medical use. Cleaning and disinfecting these foams is easy, and they are hygienic, thus making them safe for personal use.

EVA is the primary material used for automotive foams. With the use of this material, the foams gain a better structure, leading to increased flexibility, strength, and softness.

Packaging foam makes a great choice for protecting fragile and unique products. This foam is great for safeguarding fragile items from damage and impact.

We have ISO 9001, ISO 14001, and ISO 18001 certifications for our cleaning foams, and we even have health certificates. These industrial foams are of superior quality and have a long lifespan, with multiple color options available. These foams possess the important quality of not running color during washing.

Lightweight materials with physical, mechanical, thermal, electrical, and acoustic properties, have recently been developed for the military sector, and have become a popular choice for use in numerous military industries.

Unolith or foam ceilings are commonly known in the construction industry as foam. Insulation is their most essential characteristic. Their light weight makes them incredibly practical for construction. In addition to construction, closed-cell foam products are made for every home.

Foam is commonly used in various marine applications, from engine insulation and sound absorption to constructing boat seats. Moreover, it has buoyancy capabilities and offers a multitude of distinct features.

The cost-effectiveness and wide selection make foam products an appealing choice for advertising.

What is the use of EVA foam?

The market is currently in need of foams and EVA materials because of their excellent quality and multiple uses. EVA foam is made by combining vinyl acetate and ethylene through copolymerization. This foam can be used as a replacement for PVC foam, fiberglass, wood composites, and many other materials.

EVA foam offers a wide range of benefits, including its resistance to water and moisture, shock absorption, superior thermal insulation, extended lifespan, and many more. Hence, they are regularly employed in a variety of industries. Many industries use it for shoe flooring, bag interlayers, foam mattresses, packaging, and products such as yoga bricks and diving boards.

EVA, or Polyethylene Vinyl Acetate (PEVA), is a combination of ethylene and vinyl acetate. Vinyl acetate typically accounts for 10-40% of the total weight, with the rest of the material forming the polymer. Three EVA copolymers exist, each with its vinyl acetate content and purpose.

EVA foam’s strength and flexibility make it an ideal material for safety helmets, knee pads, shin guards, and more. EVA foam is protected from UV rays, making it a great choice for products that are used outdoors, like surfboard pads, boat deck mats, and hot tub insulation.

EVA stands for ethylene vinyl acetate, also referred to as PEVA for polyethylene vinyl acetate. EVA is a cushiony rubber foam that has a comparable firmness to yoga mats, but not as spongy.

EVA is usually recognized for its gentle touch, its durability in cold climates, and its ability to resist cracking. Its UV resistance makes it suitable for outdoor use, allowing it to last for a long time. EVA may have an odor similar to vinegar but it will usually go away if it is used outside or exposed to the air.

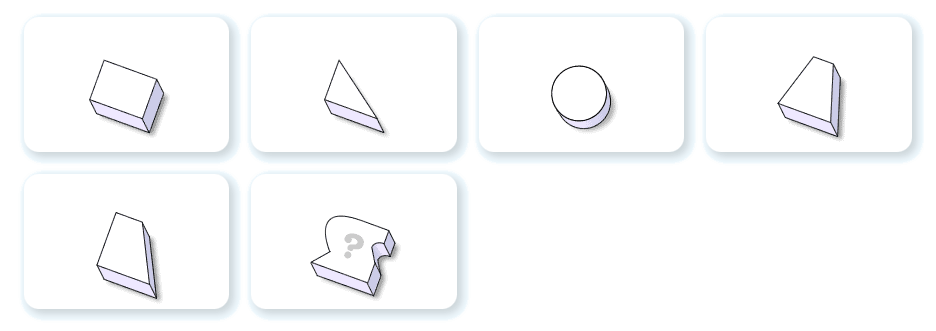

EVA foam custom cut template

We can tailor EVA foam to suit your requirements. Check out these custom-made designs:

EVA Foam’s raw material

This combination of materials is a mix of ethylene propylene diene monomer rubber and ethylene vinyl acetate polymer, giving it the best of both worlds with high gloss and resilience from EVA, and high-temperature and weather resistance from EPDM. This makes it suitable for a variety of uses.

This combination is comprised of styrene-butadiene rubber, ethylene propylene diene monomer rubber, and ethylene vinyl acetate polymer, which comes with the advantages of EPDM, SBR, and EVA, such as the lustrous shine and resilience of EVA, the heat and ozone resistance of EPDM, and the elasticity and tear strength of SBR. This makes it useful for a range of applications.

To create this high-grade compound, a mixture of styrene-butadiene rubber (SBR), ethylene-propylene monomer (EPM), and polyolefin elastomer (POE) is used. It has all the advantageous qualities of EPDM, SBR, and POE, like the right amount of flexibility and softness, plus it has a velvet-like texture from POE. It has the same temperature resistance and ozone-like resistance to water and weather as EPDM, and the durability and high tear resistance of SBR. This product is suitable for several different uses

EVA Foam Roll Characteristics

Foamiran attained certifications at the international level for ISO 9001:2015 quality management, ISO 45001 occupational health and safety, and ISO 14001 environmental management. EVA foam rolls boast a wide temperature range and keep their flexibility at lower temperatures. They endure temperatures as high as 140 degrees Celsius when under continual pressure.

It’s possible to create EVA foam rolls in a variety of sizes and shapes to fit any requirement.

EVA Foam Roll Applications

EVA foam rolls possess a consistent structure that grants them long-term flexibility and reliable color preservation. EVA foam is often produced in sheet form, with each sheet having specific characteristics depending on its intended use. Different applications of EVA foam roll are:

Furthermore, EVA foam rolls have several other uses, including in promotional materials, insulation, aerospace, ventilation, energy, the stone industry, car washes, households, special washer manufacturing, childcare, sports facilities, toy manufacturing, handicrafts, floral arrangements, and military industries.

Types of EVA Foam Roll

Foam rolls with smooth surfaces without any pattern or texture are referred to as plain foam rolls. The foam rolls come in various thicknesses, from 1 to 5 millimeters, with lengths of 50 and 100 meters, and a width of 1.5 meters, and they come in both white and black. Also, foam rolls of 5 to 10 millimeters in thickness come in 25 and 50-meter lengths and 1.5-meter widths and are available in white and black. This foam can be laminated with fabrics, leather, and other materials, making it useful for industries such as bags and footwear. If necessary, Foamiran can make foam rolls with customized sizes and depths based on customer needs.

It is possible to create ribbed foam rolls. These treads eliminate the slipperiness of the foam. This is why they are used to manufacture all sorts of slippers and single-use hotel slippers. These foam rolls are firm enough to be used for shoe sole production. Additionally, this foam roll is applied in several industrial areas. Foam rolls have a width of 1.5 meters and come in lengths of 50 and 100 meters for thicknesses between 2 to 5 millimeters, and 25 and 50 meters for thicknesses of 5 to 10 millimeters. There are a range of sizes and colors for these rolls.

Silent foam is often employed for the underlayment of parquet flooring. These foam rolls are 50 meters in length and 1.5 meters in width, with different thicknesses of 1.5 and 2 millimeters. The quality of this foam is suitable for preventing damage and decay to the parquet flooring and reducing the noise produced when walking on it. This product helps to extend the life of the parquet flooring and keeps it looking great for longer. Parquet foam can also help retain energy. Installing this roll foam under the parquet keeps cold air out and prevents heat from escaping the house.

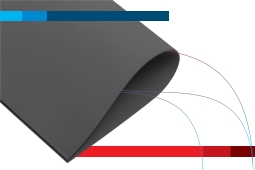

EVA Foam Sheet Characteristics

The EVA sheets are able to endure an extensive variety of temperatures, even in the cold, with the maximum temperature being 90 degrees Celsius. All of these products have been verified to meet standards under quality management systems such as ISO 9001:2015, occupational health and safety management ISO 45001, and environmental management ISO 14001.

Foamiran Company has the capability of crafting exclusive EVA sheets of different sizes.

EVA Foam Sheet Applications

EVA foam sheets are all made the same way, which helps them stay elastic and lets them take color easily. EVA foam has a range of characteristics that change based on its intended use.

EVA sheets have a wide array of applications, including items for advertising, insulation, aerospace, ventilation, energy, stone processing industries, car washes and households, production of special washers, childcare, sports facilities, toy production, handicrafts, floral arrangements, and military industries.

EVA Foam Sheet Technical Characteristics

Cellular hard foams are EVA sheets with a closed-cell structure and a density between 200 and 400 kilograms per square meter.

Cellular Low-Density Foam

Foams with a low density, ranging from 20 to 70 kilograms per square meter, are referred to as low-density foams. These foams are made of closed-cell EVA sheets.

Cellular elastic foams

EVA sheets that have a closed-cell structure and possess properties such as flexibility, immediate recoverability, high resistance to abrasion, and exceptional strength are referred to as elastic sheets.

Cellular flexible foams

EVA sheets that have a closed-cell structure and possess properties such as softness, flexibility, impact absorption, and extremely high resistance to stretching and tearing are referred to as flexible sheets.

This high-quality foam is made from ethylene vinyl acetate (EVA) and low-density polyethylene (LDPE) polymers, combining all the positive properties of both materials. It inherits the glossiness, reversibility, and high tensile strength from EVA while acquiring high-temperature resistance and chemical resistance against acids and bases from LDPE. This indicates its wide range of applications.

Cellular industrial foams

High-quality foams, utilizing premium raw materials such as EVA, are produced in various colors, dimensions, and thicknesses, with different hardness levels to cater to diverse applications.

Frequently Asked Questions

What is EVA foam?

EVA Foam, which stands for Ethylene-Vinyl Acetate, is a type of closed-cell copolymer foam. It is known for its low-density, flexible, and elastic properties, making it a versatile alternative to materials like natural rubber and vinyl.

What are the key characteristics of EVA Foam?

EVA foam has a unique set of properties that make it highly useful. These include excellent impact absorption, high water resistance, good sound insulation, and strong durability against UV rays and harsh weather conditions.

What are the common applications of EVA Foam?

Due to its versatility, EVA foam is used in a wide range of industries and products, such as:

- Sports & Recreation: For items like yoga mats, foam bricks, and flotation devices.

- Packaging: As protective inserts to absorb shocks and vibrations.

- Automotive: For sealing, insulation, and anti-vibration components.

- Medical: In the production of medical braces, orthotics, and cushioning pads.

- Construction: As a sound and thermal insulator.

- Crafts & Education: For making toys, puzzles, and various craft products.

What types of EVA foam are there?

The article mentions several types of EVA foam, including the P group, T group, polyethylene foam, and recycled EVA foam. It also notes that EVA can be blended with other materials like EPDM and SBR to create new foams with enhanced properties, such as increased resistance to oil, heat, and ozone

How can I purchase EVA foam from Foamiran?

Foamiran is a manufacturer and supplier of EVA foam. You can order it in various forms, including foam sheets, rolls, and custom-cut pieces. The company also offers additional services like foam punching, lamination, and die-cutting to meet specific customer requirements.

What is the most important feature of EVA foam?

EVA is a foam with very high reversibility. It is impact-resistant and has excellent performance against moisture and heat.

Is EVA foam used in making bags and shoes?

Yes, EVA foam is one of the widely used foams in the bag and shoe industry. Due to its lightness, softness, and good flexibility, this foam is used as the sole and sole of shoes or as a cushion for backpacks and bags.

In what shapes, dimensions, and thicknesses is EVA foam available?

EVA foam can be produced in various forms, including sheets, rolls, strips, and custom die-cut or molded parts. Foamiran offers these products in a wide variety of thicknesses, densities, and colors to meet the diverse needs of industries.

How can I order the EVA foam I need from Foamiran?

To order EVA foam in sheet, roll, or die-cut forms with your required technical specifications, you can contact our sales experts through the phone numbers listed on the Foamiran website. We are ready to provide expert consultation and place your order.

Where is EVA foam used?

Foam is used as a base material in all industries and manufacturing. It is used in medical, marine, bag making, automotive, sports, flower making, kindergarten, educational entertainment, packaging, cleaning industries, and more.