Foam’s softness and flexibility make it ideal for safeguarding delicate, fragile, or sensitive objects during transport and handling in the packaging industry. The following properties should

- be possessed by foam packaging: Sufficient Firmness and Hardness: It should be firm and rigid enough to securely hold the items, while also being soft enough to protect them from impacts.

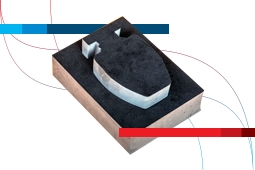

- Flexibility and Moldability: The foam should be flexible and moldable to conform to the shape of the items and provide proper protection.

- No Undesirable Reactions: The foam should not have any undesirable reactions, such as color changes or adhesion, with the packaged equipment.

- If you do not want your equipment to be damaged during transportation, you should plan for military foam equipment and delicate and valuable medical foam instruments to be placed on hard protective frames embedded in the lower part (floor).