Low-density foam ordering

What is LDPE?

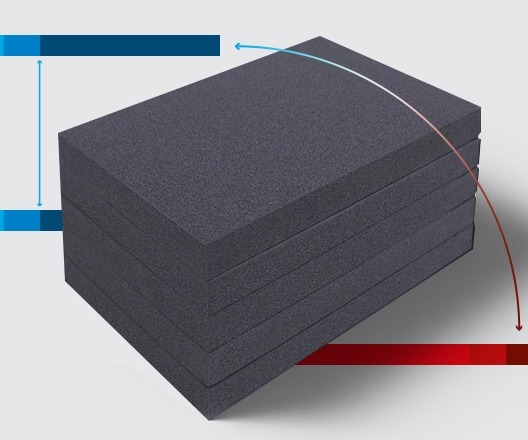

Low-Density Polyethylene (LDPE) foam is a type of foam that is known for its low weight. The density is related to the arrangement of atoms or particles. When the gap between particles is wide, it won’t have a high density and can therefore float. If the particles are crowded together with no space between them, the density will be greater. LDPE foam, due to its low density, has many favorable qualities like water resistance, chemical resistance, energy absorption, buoyancy, and cushioning qualities, which make it practical for a large variety of uses. More dense foams have a higher compressive strength, and this strength decreases as the density decreases.

A special structure known as cells is formed when both solids and gases are combined. The closed cells in Foamiran foams make them popular in a variety of industries. Different categories exist for the LDPE foams in the Foamiran assortment which vary in terms of purpose and technical details

Click on the link to download the LDPE datasheet.

Characteristics of LDPE foam

LDPE or TVRG foam is a closed cell, one of the key features of closed cell materials is the unique structure of the material, which prevents the growth of bacteria and molds.

- Cushioning properties

- Ability to absorb shock

- very light

- Waterproof, sound insulation, heat and cold

- High flexibility

- Reversible

- Low hardness

- Ability to absorb vibration

Applications of LDPE foam

Due to the characteristics of LDPE/TVRG foam, it can be used in different industries, but in this section, the most applications of foam in different industries are mentioned.

- Construction industry (as an insulating material for walls, floors, and ceilings)

- Automotive industries (for insulation, gaskets, and providing cushions inside the car and reducing the vibration and noises of the car)

- Packaging industries (packaging valuable items such as electronic parts and appliances, glass and ceramic containers, and other fine goods)

- Medical industries (packaging sensitive medical equipment and devices)

- Electronic industries (to protect electronic components and devices during transportation and handling)

- Sports goods (production of sports goods such as helmets, pads, and protective equipment, as a shock absorbing material)

Low-Density Foam (LDPE) Products

Technical Data

| Product code | Sheet dimensions (cm) | Sheet layer dimensions (cm) | Foam roll dimensions | Foam hardness | Foam density (kg/cm3) | Temperature range | Physical characteristics | Colors |

|---|---|---|---|---|---|---|---|---|

| TVRG10 | 320*155*90 | 320*155 | 50m*150cm*4mm | 20-30 Shore C | 20±5 | 40- to70°C | Low Density Foam | White, Yellow, Orange, Red, Tiffany, Phosphor Green, Blue, Lilac, Black, and Gray |

| TVRG70 | 320*155*90 | 320*155 | 50m*150cm*4mm | 20-30 Shore C | 20±5 | 40- to70°C | Low Density Foam |

Services

| Product Code | Embossing | Thermal laminate | Towel | Punch | Thermoforming | Class welding | Die Cut | CNC | Glitter | Gum |

|---|---|---|---|---|---|---|---|---|---|---|

| TVRG10 | * | * | * | |||||||

| TVRG70 | * | * | * |

Frequently Asked Questions

What is the difference between polyethylene foam and low-density LDPE foam?

In terms of density, polyethylene is a material that is divided into three categories of raw material low density, medium density, and high density. Low-density LDPA foam is a light and affordable foam that has many uses.

Is TVRG foam colored?

Yes, TVRG foams can be produced in yellow, orange, red, tiffany, phosphorescent, blue, lilac, black, and gray colors, but due to two-step baking, they are lighter in color.

Can LDPE foam be used for acoustics and sound insulation foam?

The answer to this question is a bit complicated. Currently, our R&D team has succeeded in producing a practical product to reduce environmental noise with TVRG / LDPE sound insulation foam. The important thing is that it is wrong to think that the sound and acoustics are completely zero by this foam.

What is the difference between LDPE foam and TVRG foam?

They are the same. There is no difference between them and both mean low-density polyethylene foam.