EVA foam order

What is EVA foam?

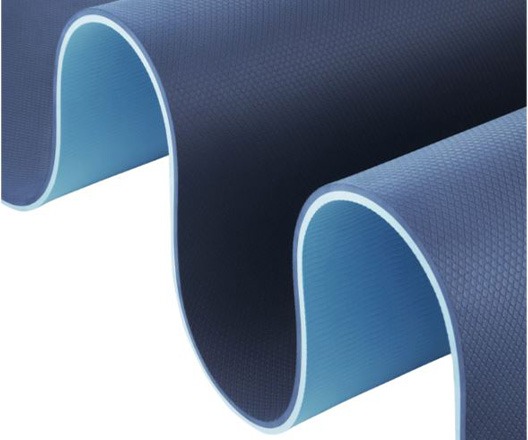

EVA foam (Ethylene-vinyl acetate) stands for ethylene-vinyl acetate closed cell copolymer foam and is one of the most widely used foams, which is known as a versatile foam. This foam is widely used in the automotive, packaging, bag and shoe, marine, cleaning, and sports product manufacturing industries and other industries.

Due to its closed cell structure, EVA foam provides several advantages, including rapid recovery of the foam after compression and flexibility, and helps to maintain its shape, in addition to shock absorption, thermal insulation, moisture resistance, buoyancy, and abrasion resistance. Chemicals are also another feature of this foam. As a UV-resistant and durable material, EVA foam is suitable for outdoor use in products such as surfboard pads, boat deck mats, and hot tub insulation.

Features of EVA foam

EVA foam is a closed-cell foam, one of the key features of closed-cell materials is the unique structure of the material, which prevents the growth of bacteria and molds

- Light

- Flexible and reversible

- A wide range of applications

- Ability to absorb shock and vibration

- Impact resistance

- Abrasion resistance

- Resistance to bad weather

- Waterproof, sound insulation, heat and cold

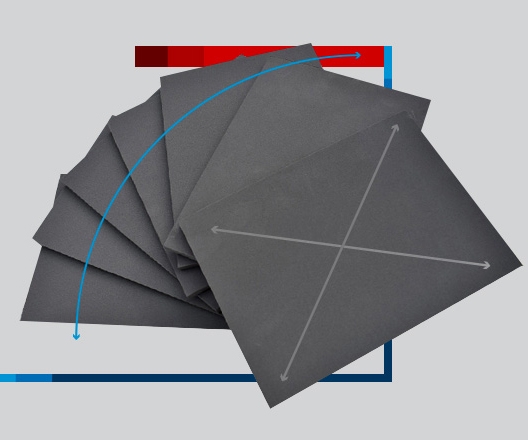

Types of EVA foam

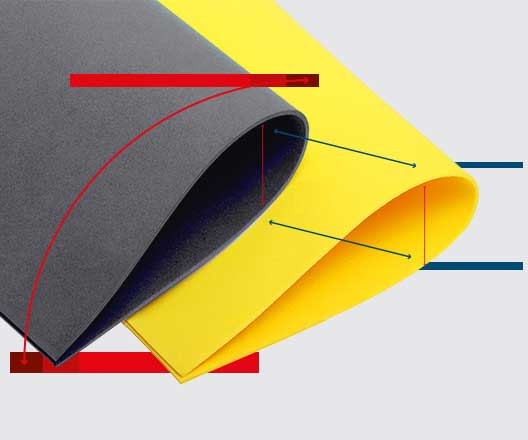

P group: a special group with softness, adhesion to the surface, and non-slip, very flexible and at the same time with proper reversibility. The presence of alpha-olefin in the ingredients of this category has made the foams of this category have a unique soft feeling. P group foams are used in various industries such as part of medical insoles, cleaning industries, shock absorbers, bags and shoes, etc.

T Group: Due to having EVA in their structure and unique formulation, this group of foams has excellent reversibility, high flexibility and the ability to be shaped by heat. Impact and buoyancy properties are also important properties in this category. T group foams are used in various industries such as automotive, construction, medicine and insulation, recreational and professional sports, adhesive tapes, shoes and packaging, shock absorbers, shock absorbers, and as buoys.

Polyethylene foam: PE foam is a durable, lightweight, flexible, and closed-cell material. It is often used for packaging industrial and agricultural goods due to its excellent vibration and insulation properties. It is also resistant to water, moisture, and chemicals, in addition, the effect of damping and absorption of vibration makes it very durable. PE’s thermal and sound insulation capabilities are also outstanding. It can also be molded or molded to create a 3D structure. For high thicknesses, it can be laminated. Polyethylene closed cell foams are used in various industries such as automotive, construction, medical and insulation, recreational and professional sports, adhesive tapes, shoes, and packaging.

Recycled EVA foam: Recycled EVA foams are produced from light polyethylene, in which EVA is not used, for this reason, the material of these foams is drier and less reversible and flexible than sheets with EVA, which is why they are affordable. Recycled EVA’s closed cell foams are used in various industries such as automobile manufacturing, footwear, sports, packaging, bag and luggage manufacturing, and industrial parts suitable for each industry.

Applications of EVA foam

Due to the characteristics of elastic foam, it can be used in various industries, but in this section, most applications of foam in various industries are mentioned.

- The Automotive industry

- Packaging industry

- Making all kinds of shoes and bags such as laptop bags (shock absorbers)

- Medical industry (types of wristbands, knee braces, medical necklaces, and medical shoe soles)

- Cleaning industry (glass washing, floor washing foams, etc.)

- Shipbuilding industry (ship bumper)

- Advertising industry (mouse pad, advertising hat)

- Construction industry (under carpet foam, silent parquet foam, and all types of sound and heat insulation foam)

EVA foam products

Technical Data

Click on the opposite link to download the technical information of EVA foam.

Services

Click on the opposite link to download EVA foam services.

Frequently Asked Questions

Where to buy EVA foam?

You can buy EVA foam from the original foam manufacturer. Foamiran is the sales center of EVA foam and the reputation of the foam industry in Iran. Currently, in addition to EVA, and EPDM foam, it also produces TVRG/LDPE foam.

Where is EVA foam used?

Foam is used as a basic material in all industries and productions. It is for the medical, marine, bag-making, automotive, sports, flower-making, kindergarten, education, entertainment, packaging, cleaning, etc. industries.

What is the most important feature of EVA foam?

EVA is a foam with very high reversibility. It is impact-resistant and has excellent performance against moisture and heat.

Is EVA foam used in making bags and shoes?

Yes, EVA foam is one of the widely used foams in the bag and shoe industry. Due to its lightness, softness, and good flexibility, this foam is used as the sole and sole of shoes or as a cushion for backpacks and bags.