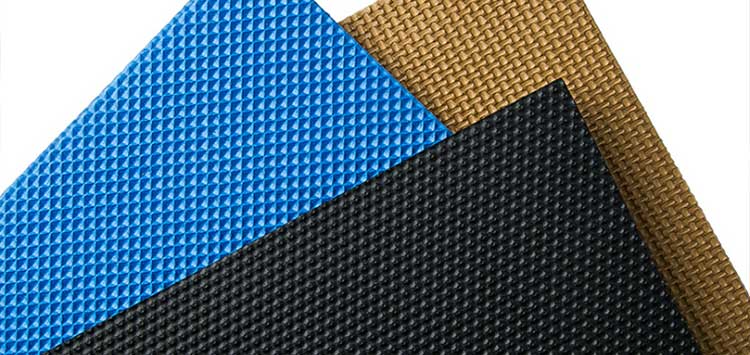

Low-density polyethylene (LDPE) sheets are in high demand for their low density. Its affordability and quality have made it a popular choice in many industries. LDPE sheets can be found in a wide variety of industries, like medical mattress production, bags and footwear making, packaging, converting, automotive, and cleaning. LDPE sheets are a type of closed-cell foam, which are low density and offer many advantages, such as water resistance, chemical protection, buoyancy, and being lightweight. Foams with higher density have a greater compressive strength, which lowers as the density decreases.

The LDPE sheets have international approval for quality control ISO9001:2015, occupational health and safety ISO45001, and environmental management ISO14001.