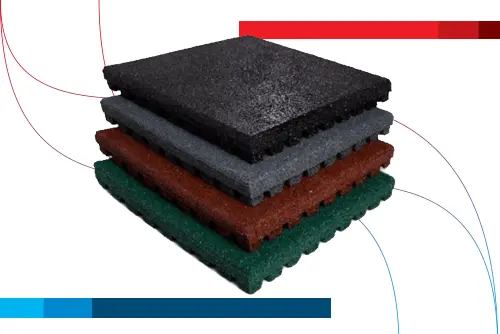

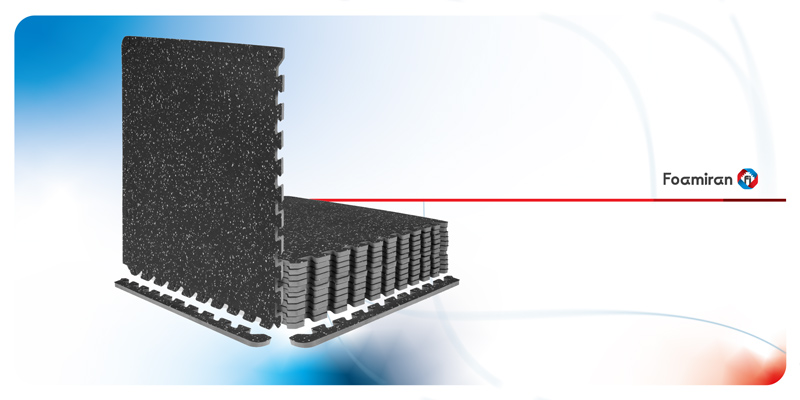

Granular flooring is a type of flooring made from multiple layers of materials such as rubber, rubber granules, resin, etc. These granules are typically obtained from recycled rubber tire casings. By combining these materials, a soft and flexible surface with shock-absorbing and abrasion-resistant properties is created. This type of flooring is commonly used for covering floors in sports halls, preschools, parks, equestrian competitions, and more. Additionally, granulated flooring is also used as a floor covering for some recreational centers and water facilities, such as pool decks and saunas.

Granulated flooring is a safety assurance in environments like children’s play areas and sports clubs, making its purchase essential for ensuring safety. Furthermore, these flooring solutions provide a comfortable environment for walking and exercising.